8

2-3.2 Handling / Lifting

WARNING

CAUTION

Pump and components are heavy. Failure to properly lift

and support equipment could result in serious physical

injury or damage to the equipment. Steel-toed shoes

must be worn at all times.

Use a forklift or an overhead crane with sufficient

capacity to move the equipment. Failure to do so

can result in physical injury or equipment damage.

WARNING:

All applicable regulations and standards must be followed when lifting equipment.

Assembled equipment and their components are very heavy. Failure to properly lift and support equipment can

result in serious physical harm and/or damage to the equipment.

Lift equipment only at the identified lifting points. Devices such as hoist rings, shackles, slings, straps, chains,

spreaders, etc. must be rated to support the entire weight of equipment.

Equipment and their components can be heavy. Use proper lifting methods and wear steel-toed shoes at all

times.

Do NOT lift equipment by shaft ends.

Do NOT combine or interchange different lifting methods.

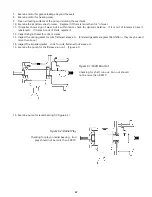

Pump Type

Lifting Method

Bare Pump Only

Use a suitable sling attached properly to the casing, flanges, and/or frame.

Base Mounted Pump

Use suitable slings attached properly to the casing and the motor or baseplate. Use

lifting lugs or rings on the baseplate when available.

For concrete polymer baseplates, see the baseplate IOM manual for additional lifting

instructions.

Proper Lifting Method Examples

Figure 1:

Bare Pump Lifting Method

Figure 2:

Pump and baseplate lifting method.

Figure 3:

Pump, base and motor lifting method.

Figure 4:

Lifting method for baseplates

using lifting lugs or rings.