19

5-3 MAINTENANCE OF BEARINGS

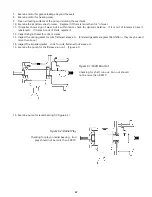

5-3.1 Oil Lubricated Bearings

WARNING

TRUFLO® Pumps are shipped without oil. Oil lubricated

bearings must be lubricated at the job site.

1.

Remove fill plug and add oil until level is at the center of sight glass. Replace fill plug.

2.

Change the oil after 200 hours for new bearings, thereafter every 2000 operating hours or 3 months. (Whichever

comes first.)

Table 4

Oil Volumes

Frame

Pints

Milliliters

Group 1

1.0 pt.

400 mL

Group 2

2.6 pt.

1250 mL

Group 3

3.0 pt.

1400 mL

Note: High quality turbine oil with rust and oxidation inhibitors should be used. For the majority of operational

conditions, bearing temperature will run between 120

F (50

C) and 180

F (82

C). In this range, an oil of ISO viscosity

grade 68 at 100

F (40

C) is recommended. If bearing temperatures exceed 180

F (82

C) use ISO viscosity grade 100

with bearing frame cooling or finned-tube oil cooler. For operating temperatures above 350

F (177

C), synthetic

lubrication is recommended.

Acceptable lubricants:

Exxon

Teresstic EP 68

Shell

Tellus Oil 68

Philips

Mangus Oil 315

Chevron

GTS Oil 68

Mobil

DTE 26 300 SSU @ 100

F (38

C)

Sunoco

Sunvis 968

Royal Purple

SYNFILM ISO VG 68 Synthetic Lube

Acceptable synthetic lubricants:

Mobil

DTE Oil BB or SHC 630

Shell

Marlina 220 or Tellus 220

Royal Purple

Synfilm GT 220 or Synergy 220