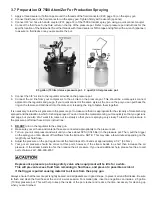

3.7 Preparation Of 7500 AtomiZer For Production Spraying

1. Apply a thread sealer or Teflon tape around the threads of the fluid connector (#29, page 33) on the spray gun.

2. Connect fluid hose to the fluid connector on the spray gun. Tighten firmly with a wrench (spanner).

3. Connect 3/8” air hose to handle coupler (#37, page 33) of the 7500 AtomiZer spray gun using a quick connect coupler.

4. Connect the fluid hose to the fluid outlet on the top of the pressure pot. Refer to your pressure pot instructions for the

specific location of the fluid outlet. Seal the threads with thread sealer or Teflon tape and tighten with a wrench (spanner)

to assure no fluid leaks once you pressurize the pot.

2.5 gallon (10 litre) deluxe pressure pot. 2 quart (2 litre) pressure pot.

5. Connect the 3/8” air line to the regulator air outlet on the pressure pot.

6. Connect the air line from your compressor to the air inlet on the pressure pot. This should be a male quick connect

adjacent to the regulator and gauge. If your quick connect is the same style as the one on the pot you can pull back the

ring on the female end and insert into the male end, releasing the ring to fasten them together.

It is necessary to test the air pressure in the pressure pot to make sure that it is appropriate for the viscosity of material being

sprayed and the situation in which it is being sprayed. You don’t want the material coming out too quickly so that you get runs

and sags, but you also don’t want it to come out too slowly so that you are spraying very slowly. To test the air pressure in

the pressure pot follow these simple instructions:

1. DO NOT

turn on the regulator to the spray gun.

2. Make sure your air hose and material hose are connected appropriately to the pressure pot.

3. Turn on your air compressor and wait until you have about 5PSI (0.345 Bar) in the pressure pot. Then, pull the trigger

on the spray gun until a stream of fluid flows from the tip/nozzle. NOTE: This may take a few minutes depending on the

length of your fluid hose.

4. Adjust the pressure on the pot regulator until the fluid drops off or bends at approximately 2-1/2 “ (6.35cm).

5. Your pot air pressure should be correct at this point, however, if the stream bends too short then increase the air

pressure. If the stream bends too far, then reduce the air pressure. If you need additional help, please feel free to call

our technicians at 1-888-900-4857.

Depressurize pressure pot using safety valve when equipment will be idle for a while.

This will prevent excess fluid from remaining in fluid hose, and prevent a possible accident

if the trigger is pulled causing material to stream from the spray gun.

Always ensure that the remote pot is tightly sealed, and all gaskets are in good shape, to prevent air and fluid leaks. Be sure

to flush and clean the fluid hose at the end of a work session. For smaller jobs, insert a one gallon can inside a 2.5 gallon

(10 litre) pressure pot. This will help to keep the inside of the pot cleaner and reduce the time necessary for cleaning up

when you are finished.

Summary of Contents for Apollo 7500 AtomiZer

Page 32: ...8 Diagram Parts List...