7500C Pressure

Settings - HS Air Cap

Inlet

Air Cap

22PSI

10PSI

20PSI

9PSI

19PSI

8PSI

17PSI

7PSI

15PSI

6PS

13PSI

5PSI

11PSI

4PSI

9PSI

3PSI

6PSI

2PSI

7500C Pressure

Settings - Std. Air Cap

Inlet

Air Cap

23PSI

10PSI

21PSI

9PSI

18PSI

8PSI

16PSI

7PSI

14PSI

6PS

12PSI

5PSI

9PSI

4PSI

7PSI

3PSI

4PSI

2PSI

7500C Pressure

Settings - HS Air Cap

Inlet

Air Cap

23PSI

10PSI

21PSI

9PSI

18.5PSI

8PSI

16.5PSI

7PSI

14PSI

6PSI

12PSI

5PSI

9.5PSI

4PSI

7PSI

3PSI

5PSI

2PSI

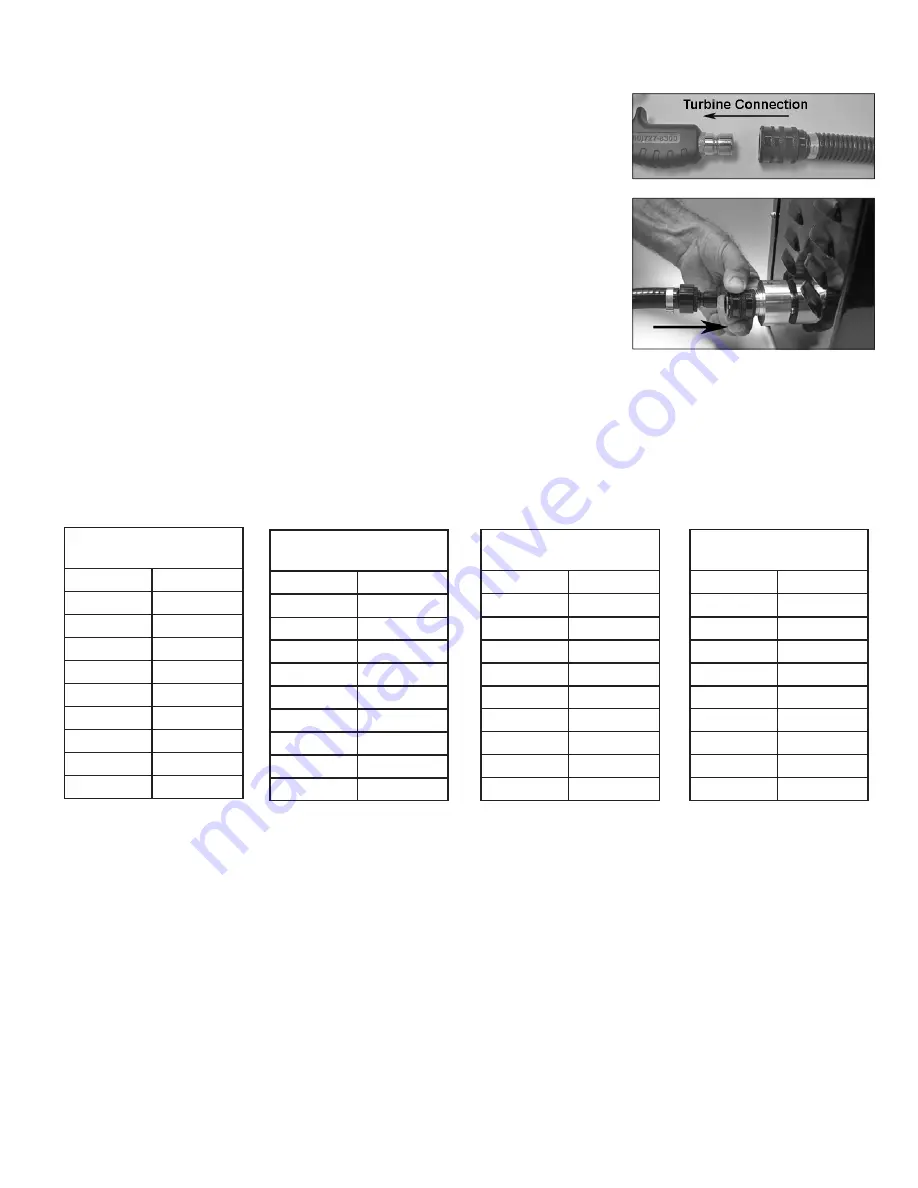

4.3 Using The 7500 AtomiZer With A Turbine System

After set up of spray gun is complete:

1. Connect the air hose to the male air quick connect (#27, page 33) located at the

bottom of the spray gun handle.

2. Connect the other end of the air hose to your Turbine.

3. Turn on your turbine. Make sure air is always coming out of the air relief

mechanism. (If external).

4. You are ready to spray and apply coating to your work, follow general spraying

instructions.

4.4 Using The 7500 AtomiZer With Compressed Air

Be sure air lines are clean, moisture and oil free. Drain any in-line filters. Be sure the compressor you are using will maintain

continuous air (flow pressure) to continuously supply the spray gun. Generally a 3hp air compressor with a 20 gallon (75

liter) tank will maintain continuous air at 13PSI - 19PSI (0.9 Bar - 1.31 Bar). A larger compressor might be necessary if

spraying high viscosity materials at higher PSI. Set the regulator to the spray gun as follows: 6 PSI - 12 PSI (0.414 Bar - 0.83

Bar) for thin, low viscosity fluids. 13PSI - 23PSI (0.9 Bar - 1.59 Bar) for medium to high viscosity fluids.

Without Air Regulator Without Air Regulator With Air Regulator With Air Regulator

7500C Pressure

Settings - Std. Air Cap

Inlet

Air Cap

22PSI

10PSI

20PSI

9PSI

19PSI

8PSI

17PSI

7PSI

15PSI

6PSI

13PSI

5PSI

10PSI

4PSI

8PSI

3PSI

5PSI

2PSI

Chart shown with Standard

Air Cap, Turbine coupler

and high flow fittings.

Chart shown with High

Solids Air Cap, Turbine

coupler and high flow

fittings.

Chart shown with Standard

Air Cap, Turbine coupler

with 1/4” x 1/4” adapter

and regulator - no high flow

fittings.

Chart shown with High

Solids Air Cap, Turbine

coupler with 1/4” x 1/4”

adapter and regulator - no

high flow fittings.

* All tests performed with Material Screw open 2 full turns, full trigger pull and 3/8” x 20’ air hose with high flow fittings

from wall regulator forward. High flow fittings only reduce the sealed pressure needed to achieve 10PSI at the air cap, but

does not reduce the amount of inlet flow pressure needed to achieve 10PSI Air Cap pressure. Pressure’s quoted are flow

pressures, sealed pressure’s will vary depending on the size of your air compressor and any restrictions in the air lines.

Use these settings as a guideline. Always use the lowest pressure that produces the best atomization and visual results.

This will provide the highest efficiency and lowest overspray. You are ready to spray. Follow the general spraying directions

for the best operation of your spray gun. For further assistance please visit our website at www.hvlp.com or call our customer

service associates at 888-900-4857 (HVLP).

Summary of Contents for Apollo 7500 AtomiZer

Page 32: ...8 Diagram Parts List...