7.

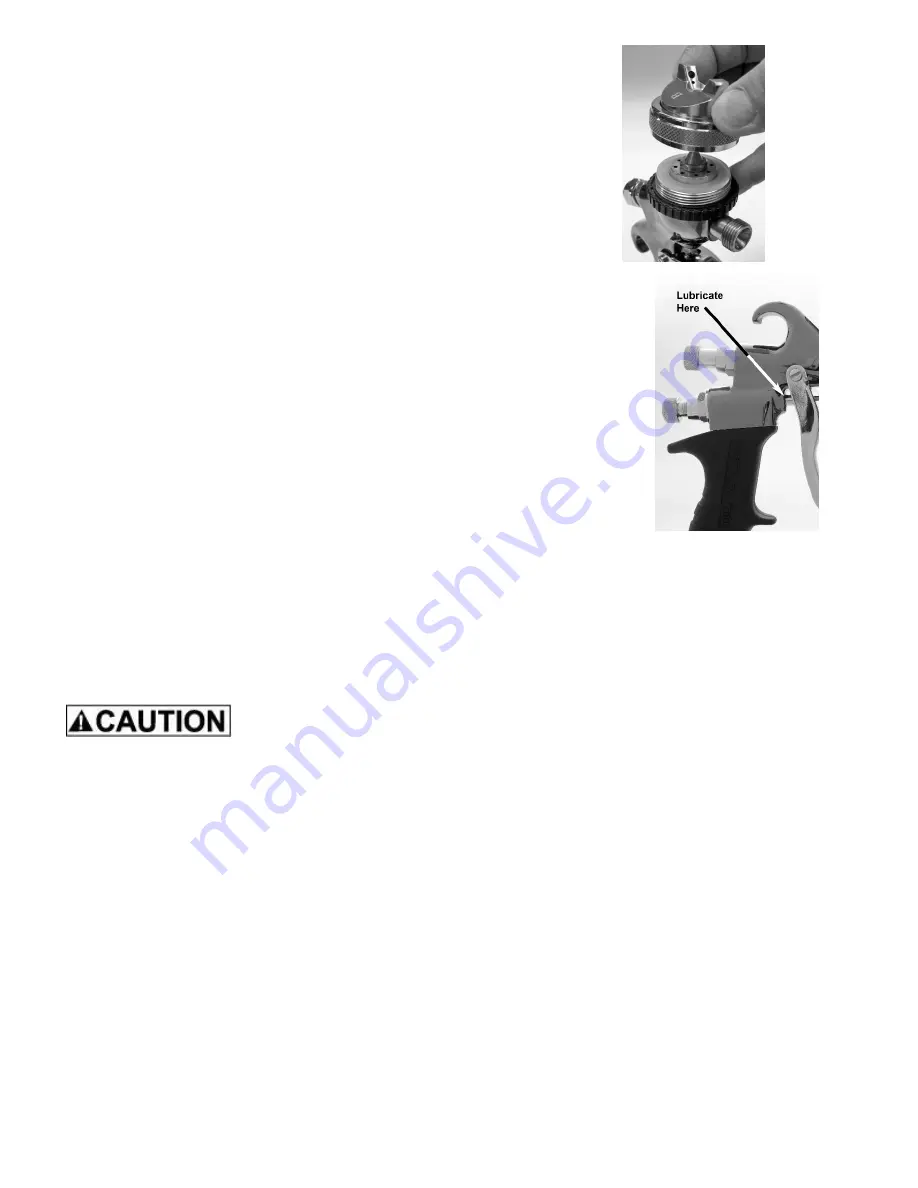

Install air cap and air cap ring. Spray gun is now re-assembled and ready to use.

Periodically, use Apollo lubricant to lubricate the air valve bushing as shown.

NOTE:

When

reassembling

your

spray

gun,

do

not

tighten

down

the

Air

Cap

Ring

(#1).

This

will

ensure

that

if

there

is

any

material

residue

on

the

threads

it

will

not

dry

and

seal

itself

to

the

Air

Cap

(#2).

Pressure will remain in the spray cup when unit is off. If you pull the trigger back, a stream

of fluid will flow. To prevent accidents, turn material flow screw clockwise until it is

completely closed. The trigger is now locked in the closed position.

To relief the cup pressure prior to opening the cup use the twist connector located between

the check valve and the cup lid. Undo the connector and the air pressure will exhaust

through the tube. If you don’t relieve the air pressure prior to opening the lid on the cup,

paint can fly out and down the side of the cup.

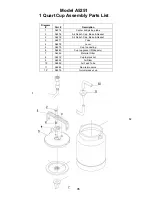

Summary of Contents for Apollo 7500 AtomiZer

Page 32: ...8 Diagram Parts List...