4.6 Understanding Your Viscosity Meter

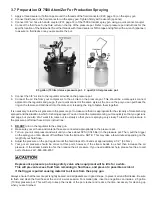

Using the APOLLOSPRAY® viscosity meter is an accurate way of measuring the thickness/viscosity of a coating in order

to ensure a fine finish. The viscosity meter will accurately measure many different varieties of materials including, but not

limited to: Lacquers, Sealers, Enamels, Stains, Oils and Waterbornes.

TO USE:

Take a stopwatch, the APOLLOSPRAY® viscosity meter and the coating/

material/paint to be measured.

1. Dip the Viscosity meter into the coating.

2. Start the stopwatch as soon as you pull the cup out of the coating.

3. The coating will run out of the hole in the bottom of the cup in a steady

stream.

4. As soon as you see the FIRST break in the stream, stop the watch. The

time shown is equivalent to #2 Zahn seconds.

5. Clean the cup and store.

If the time you get is more than the recommended or desired time, then you

need to thin your material. Use the appropriate thinner to the correct proportion

for your mixture. Retest, following steps 1-4. Continue to thin until the desired

viscosity is reached or until you reach the maximum thinning recommended by

the manufacturer of the coating you are trying to spray. For further assistance please visit our website at www.hvlp.com or

call our customer service associates at 888-900-4857 (HVLP).

4.7 Know Your Coating Properties

Coatings are a blend of resins and additives to create a product that will provide a protective and beautifying surface to your

work piece. Different resins have different properties. It is important to use the correct coating to achieve a desired result.

Manufacturers of coatings can control the resin solids content, production viscosity, sheen, color, flow-out enhancement and

other properties as well. Some products offer ways to adjust the coating properties such as speeding up or slowing down the

drying time, adding catalysts to strengthen the molecular bond or adding flatting agents to lower the sheen. Manufacturers

will often give some guidelines on how to thin their product for spray application. There are many different types of spray

equipment in use. Coatings manufacturers cannot address all of them. It is important for the finisher to understand the spray

equipment and to use common sense to arrive at the correct fluid viscosity to produce the best possible results with the

selected coating and the equipment being used.

4.7.1 Your Choice Of Coatings And Viscosity

Extremely thin, watery or light bodied fluids such as inks, aniline dyes and oil stains can generally be used straight from

the can. Most water based finishing products are also formulated to be used straight from the can without thinning with a 3

stage or larger turbine. Most other coating products will need to be thinned anywhere from 10% to 50% depending on the

available air pressure of the turbine model and the properties of the coating selected.

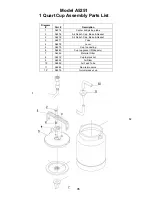

Summary of Contents for Apollo 7500 AtomiZer

Page 32: ...8 Diagram Parts List...