TrojanThree User Guide

Page | 58

•

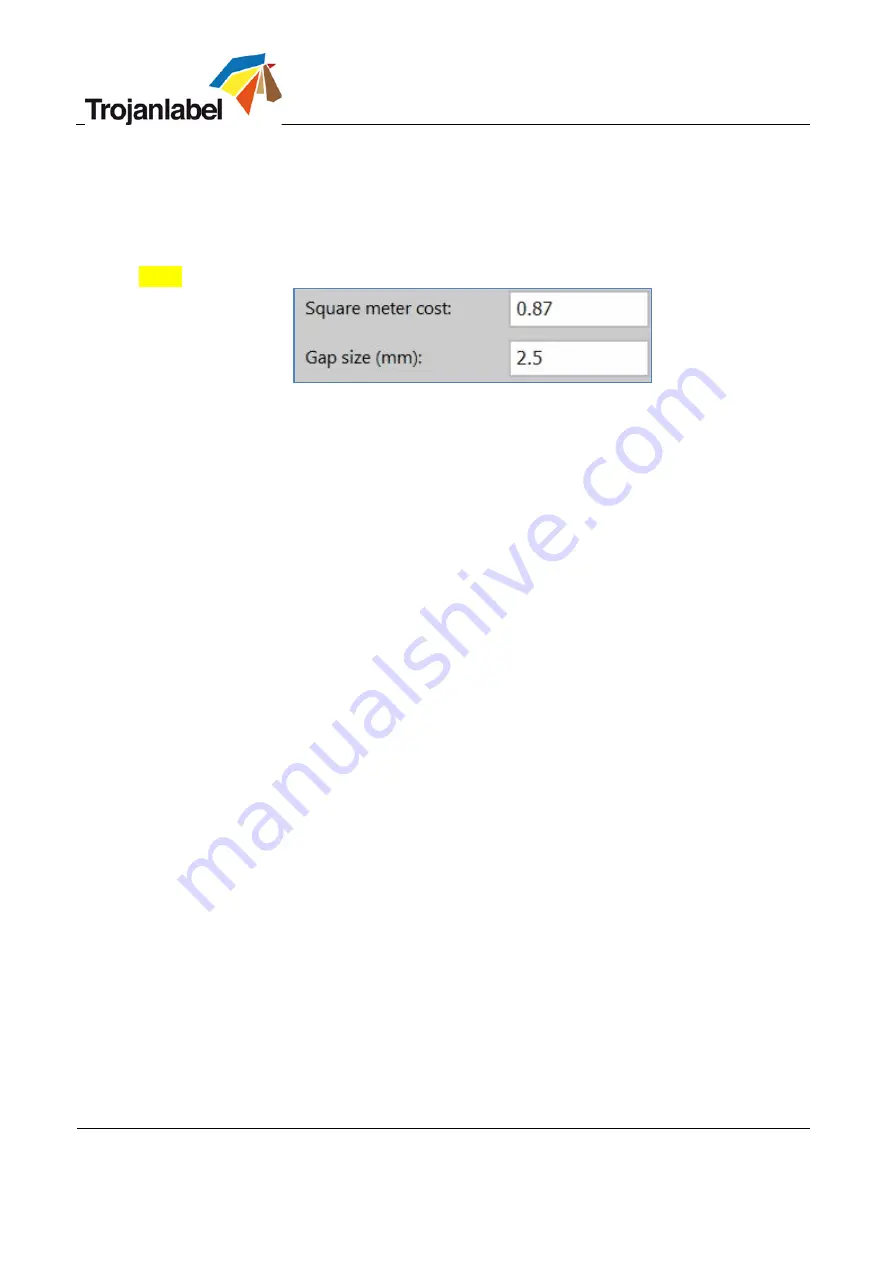

Unit cost /Square meter cost:

Price of

1 printed unit (like a cardboard box or paper bag) or price of

one label for die cut material or Square meter price for Continuous and Blackmark label material.

Used for total cost/label calculation. (See section 11.2.3). The field changes from unit to square

meter cost when TOF mode is changed from diecut to continuous or blackmark.

•

Gap size (only in continuous mode):

Setting the gap size between printed labels.

NOTE: Maximum gap size is 65mm.

Setting label gap size in continuous mode