2HJ/2HK

2-2-2

5.

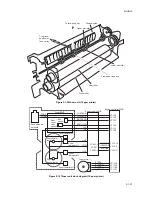

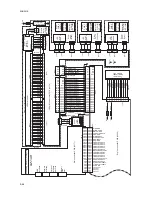

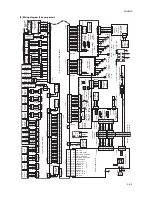

Engine relay PWB........................................ Interconnects the engine controller PWB and the electrical parts.

6.

Sensor PWB ................................................ Consists the top cover/paper feed unit switch, side cover switch, top

cover switch 1, paper gauge switch 1/2, registration sensor, and, wiring

relay circuit.

7.

Operation panel PWB .................................. Indicates the LCD message display and LED indicators. Controls key

inputs.

8.

Bias high voltage PWB ................................ Generates the developing magnet roller bias, developing sleeve bias,

and secondary transfer bias.

9.

Main high voltage PWB................................ Generates the main charger high voltage and primary transfer rollers

bias.

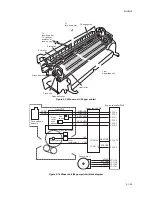

10. Waste toner full sensor PWB ....................... Detects the waste toner box being full.

11. Waste toner full sensor ................................ Section of LED light emitting for waste toner detection.

12. MP tray paper sensor................................... Detects paper misfeed in the MP tray.

13. Humidity sensor ........................................... Detects the ambient humidity.

14. Temperature sensor ..................................... Detects the ambient temperature.

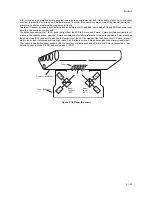

15. Registration sensor ...................................... Detects the timing of primary feeding.

16. Paper gauge sensor 1.................................. Detects the paper remaining amount level.

17. Paper gauge sensor 2.................................. Detects the paper remaining amount level.

18. Paper full sensor .......................................... Detects whether the face-down tray is full.

19. Toner ID sensor............................................ Measures image density for color calibration.

20. Envelope feeder install sensor ..................... Installing detection of optional envelope feeder.

21. Top cover/feed unit switch............................ Shuts off 24 V power line when the top cover is opened.

22. Top cover switch 1 ....................................... Detects the top cover open.

23. Top cover switch 2 ....................................... Detects the top cover and left side cover open.

24. Side cover switch ......................................... Shuts off 24 V power line when the left side cover is opened.

25. Power switch................................................ Turns ON/OFF the AC power source.

26. Cassette size switch .................................... Detects the paper size dial setting of the paper setting dial.

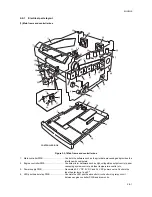

27. Feed motor................................................... Drives the paper feed section.

28. Fuser motor.................................................. Drives the primary transfer cleaning unit, fuser unit and exit section.

29. Primary transfer motor ................................. Drives the primary transfer unit.

30. Drum motor 1 ............................................... Drives the magenta drum unit.

31. Drum motor 2 ............................................... Drives the cyan drum unit.

32. Drum motor 3 ............................................... Drives the yellow drum unit.

33. Drum motor 4 ............................................... Drives the black drum unit.

34. Toner motor 1............................................... Replenishes the magenta developer with toner.

35. Toner motor 2............................................... Replenishes the cyan developer with toner.

36. Toner motor 3............................................... Replenishes the yellow developer with toner.

37. Toner motor 4............................................... Replenishes the black developer with toner.

38. Ozone fan motor 1 ....................................... The exhaust gas of ozone.

39. Ozone fan motor 2 ....................................... The exhaust gas of ozone.

40. Main fan motor ............................................. Dissipates heat from the fuser unit.

41. Drum motor cooling fan motor ..................... Dissipates heat from the drum motors.

42. Controller box fan motor .............................. Dissipates heat from the controller box.

43. Developer drive stop motor .......................... Detaches and makes stop the drive transmission of developers other

than black developer at the time of monochrome printing.

44. MP tray feed solenoid .................................. Controls the primary paper feed from the MP tray.

45. Registration clutch ....................................... Controls the second paper feed.

46. Feed clutch .................................................. Controls the paper cassette paper feed.

47. AC inlet ........................................................ Connects the AC power source.

48. Expanding memory (optional) ...................... For expanding main RAM.

49. Expanding memory card (optional) .............. Expands the print job function.

50. Expanding board (optional) .......................... Expands the interface, network interface card or hard disk unit.

*

1

: 16 ppm printer only.

Summary of Contents for CLP3316

Page 1: ...Service Manual Color Printer CLP 3316 CLP 3520 X First Edition Date 24 10 2006 2HKSM060 ...

Page 2: ...Service Manual Color Printer CLP 4316 CLP 4520 X First Edition Date 24 10 2006 2HKSM060 ...

Page 6: ...This page is intentionally left blank ...

Page 12: ...This page is intentionally left blank ...

Page 20: ...2HJ 2HK 1 1 8 This page is intentionally left blank ...

Page 32: ...2HJ 2HK 1 2 12 This page is intentionally left blank ...

Page 138: ...2HJ 2HK 1 6 4 This page is intentionally left blank ...

Page 168: ...2HJ 2HK 2 1 30 This page is intentionally left blank ...

Page 172: ...2HJ 2HK 2 2 4 This page is intentionally left blank ...

Page 188: ...2HJ 2HK 2 4 6 This page is intentionally left blank ...