2HJ/2HK

1-6-2

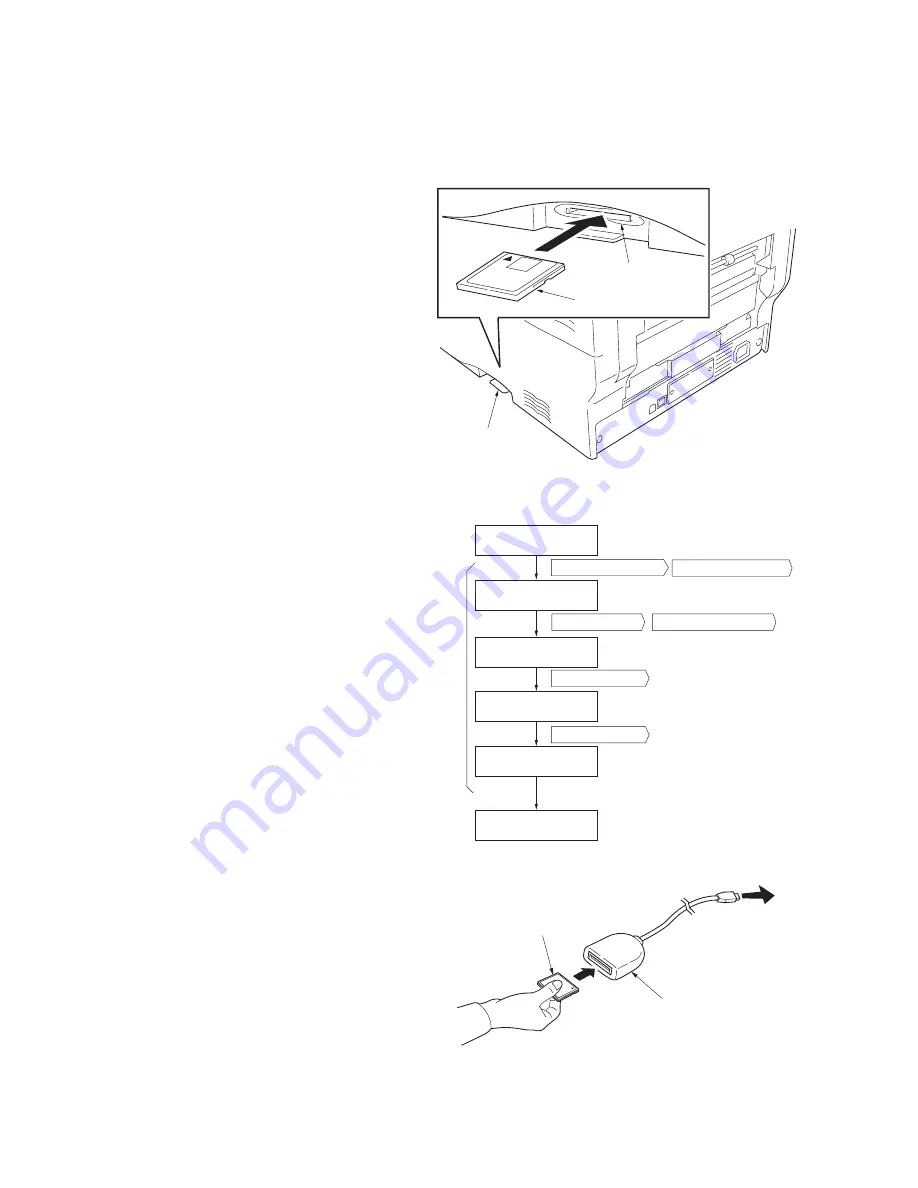

(1) Downloading the firmware from the memory card

The procedure below provides how to download firmware from a memory card. Note that you can download both the sys-

tem and engine firmware at a time.

Procedure

1. Turn printer power off.

2. Insert the memory card into the printer's

memory card slot.

Figure 1-6-2

3. Turn printer power on.

4. Press MENU key on the printer's operation

panel and carry out the memory card for-

matting procedure (1).

5. When formatting is complete, turn printer

power off.

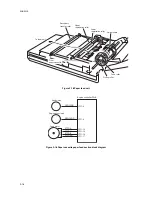

Figure 1-6-3

6. Remove the formatted memory card from

the memory card slot.

7. Insert the memory card to the PC's slot or to

the adaptor.

8. Copy the firmware file to download to the

root directory of the memory card.

9. Remove the memory card from the PC's slot

or the adaptor.

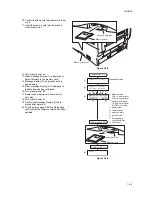

Figure 1-6-4

Memory card slot

Memory card slot

Memory card

Message display

Operation panel keys

Press the MENU key.

Press the OK key.

Press the OK key.

Press the

key.

Press the

or

key.

Press the

or

key.

(Format information is

automatically printed.)

(1)

Memory Card >

>Format

>Format ?

Processing

Ready

Ready

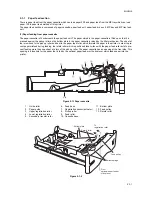

To PC

Memory card

Adapter

(Memory card reader/writer)

Summary of Contents for CLP3316

Page 1: ...Service Manual Color Printer CLP 3316 CLP 3520 X First Edition Date 24 10 2006 2HKSM060 ...

Page 2: ...Service Manual Color Printer CLP 4316 CLP 4520 X First Edition Date 24 10 2006 2HKSM060 ...

Page 6: ...This page is intentionally left blank ...

Page 12: ...This page is intentionally left blank ...

Page 20: ...2HJ 2HK 1 1 8 This page is intentionally left blank ...

Page 32: ...2HJ 2HK 1 2 12 This page is intentionally left blank ...

Page 138: ...2HJ 2HK 1 6 4 This page is intentionally left blank ...

Page 168: ...2HJ 2HK 2 1 30 This page is intentionally left blank ...

Page 172: ...2HJ 2HK 2 2 4 This page is intentionally left blank ...

Page 188: ...2HJ 2HK 2 4 6 This page is intentionally left blank ...