18

DC7000 ANTIQUE

MAINTENANCE

(The following maintenance procedure must be

carried out for commercial and health care

premises, but is not necessarily required for

domestic installations).

Maintenance of the unit is required to ensure

continued performance after installation and that

it continues to provide scald prevention.

The frequency of routine maintenance of the

internal of the valve will depend mainly on the

water supply condition. Local knowledge will

dictate suitable intervals. In addition, the following

precautions should be observed:

a)

Initially check the strainer baskets (fig.33) for

debris once every three months and clean if

necessary. This period can be increased if

appropriate once the general condition and

cleanliness of the water is established. Where the

water supplies come from beneath (rising) the

mixer valve, lifting out the strainer basket may not

remove all of the trapped debris. Full flushing out

may be necessary if debris is found or suspected.

b)

Perform a thermal shut off test every three

months, and check the maximum temperature

setting. See the ‘Commissioning’ section for the

details of this test and re-adjustment of the

maximum temperature setting if required.

c)

If the maximum water temperature varies by

more than 2°C from the commissioned setting

then ensure the strainers are clean and that the

isolating valves are fully open. Test the non return

valves as described below. If these tests do not

highlight the reason for the temperature variation,

then follow the procedure below for investigating

failure of the thermal shut off test.

d)

If the mixer valve fails the thermal shut off

test then remove the knobs, faceplate and control

valve cover. Check the internal surface for scaling.

If the body requires descaling then it should be

removed from the pipework to carry this work out

– the valve should be able to be removed through

the aperture without breaking tiles. All rubber

parts must be removed prior to descaling. The

slide valve seal (fig.34) located inside the body

should always be replaced with a new seal after

removal. Maintenance kits are available which

contain ‘O’ rings and/or the thermostatic element.

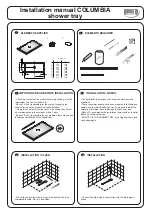

Inlet strainer body

Strainer

basket

Swivel

seal

15mm

ferrule

15mm

compression

nut

End cap

Cap seal

On/off unit

Seal

Retaining nut

1/2" Washer

Fig.33

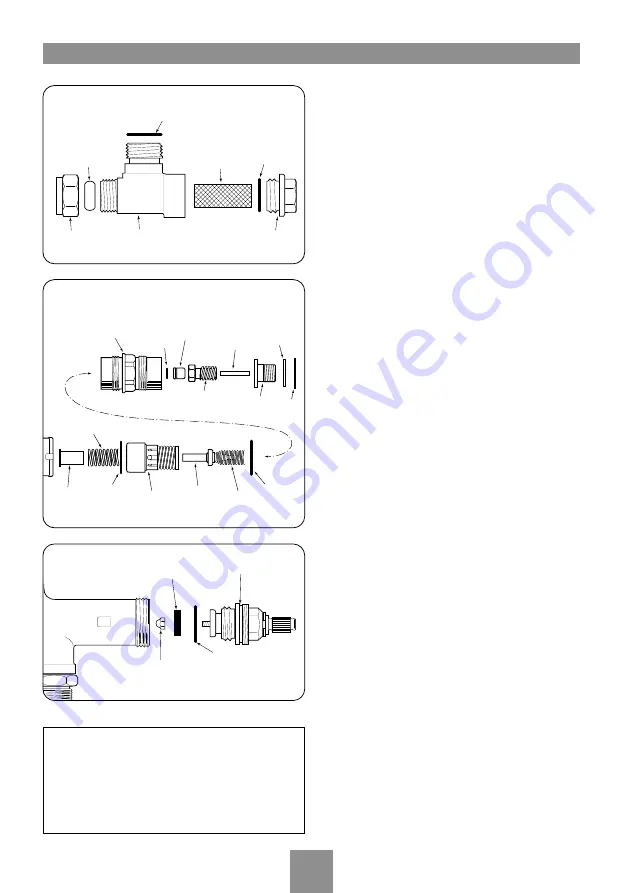

Valve cover

Piston

seal

Temp

adjustment

piston

Control

stem

Max temp

adjustment

screw

Temp knob

adaptor

Thrust

washer

Adaptor

circlip

Baffle

tube

Return

spring

Slide valve

seal

Slide valve

sub assembly

Thermostat

element

Element

spring

Valve cover

seal

Fig.35

Fig.34

When cleaning the external faceplate and

knobs, never use cleaners containing

abrasives or solvents as they may damage

the chrome plating. Use only soap and a

soft cloth.

Summary of Contents for DC7000 Antique

Page 2: ...DC7000 ANTIQUE UKAS QUALITY MANAGEMENT 003...

Page 25: ...23 DC7000 ANTIQUE...

Page 26: ...DC7000 ANTIQUE 24...

Page 27: ......