18-CD20D1-18

15

Installer’s Guide

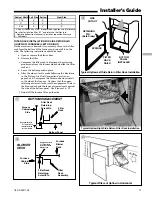

ELECTRICAL CONNECTIONS

Make wiring connections to the unit as indicated on enclosed

wiring diagram. As with all gas appliances using electrical

power, this furnace shall be connected into a permanently live

electric circuit. It is recommended that it be provided with a

separate “circuit protection device” electric circuit. The

furnace must be electrically grounded in accordance with

local codes or in the absence of local codes with the National

Electrical Code, ANSI/NFPA 70 “latest edition” or Cana-

dian Electrical Code, CSA C22.1, if an external electrical

source is utilized.

All field supplied wiring must conform with the temperature

limitation for Type T wire [63° F (35° C)], when installed in

accordance with these instructions and wiring diagrams

supplied with the furnace. A disconnecting means must be

located within sight from, and readily accessible to, the

furnace.

Refer to the SERVICE FACTS literature for unit wiring

diagrams in addition to the diagram inside the blower door.

FIELD WIRING DIAGRAMS

1.

Be sure power agrees with equipment nameplates.

2.

Low voltage (24 volt wiring) to be No. 18 A.W.G. min.

3.

Grounding of equipment must comply with local codes.

4.

Set thermostat heat anticipator per unit wiring diagram.

5.

These leads provide 115V. power for connection of electronic

air cleaner and humidifier MAX. load 1.0 amps each.

6.

When a single stage heating thermostat without fan switch

is used, no wiring on "G" terminal is used.

7.

W1 and W2 must be jumpered together for proper operation.

Second stage heat will begin 10 minutes after first stage.

8.

Set dip switches with power off per installation instructions

to set airflow and indoor fan off delays.

9.

Continuous fan airflow can be increased by adding this jumper.

10.

This wire is only for thermostats requiring connection to

transformer common terminal.

11.

Optional humidistat is to be connected between R and BK. Factory installed jumper R

to BK on the circuit board must be cut if optional humidistat is used. The jumper must

also be cut when applying an airflow command signal to the BK input such as with the

variable speed single-zone and multi-zone system controllers. On single speed cooling

only/non-heat pump systems, jumper Y to O for proper operation of the delay profiles

and the humidistat. For two compressor or two speed systems, jumper YLo to O.

W14

SEE

NOTE 10

SEE

NOTE 9

Y1/Ylo

W14 JUMPER

SEE NOTE 11

FIELD ADDED JUMPER

W1 TO W2.

2ND STAGE WILL FIRE

10 MINUTES AFTER 1ST.

From Dwg. B342027 Rev. 0

SEE

NOTE 6

B/C

B/C

TO 115 V 1 PH.,

60 HZ., POWER

SUPPLY PER

LOCAL CODES

HUM SEE

NOTE 5

EAC SEE

NOTE 5

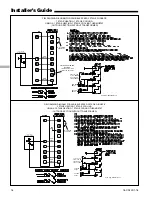

FIELD WIRING DIAGRAM FOR VARIABLE SPEED 2 STAGE FURNACE

1 STAGE HEATING

USING A 1 STAGE HEATING THERMOSTAT

NO COOLING

1. Be sure power agrees with equipment nameplates.

2. Low voltage (24 volt wiring) to be No. 18 A.W.G. min.

3. Grounding of equipment must comply with local codes.

4. Set thermostat heat anticipator per unit wiring diagram.

5. These leads provide 115V. power for connection of electronic

air cleaner and humidifier MAX. load 1.0 amps each.

6. This wire is only for thermostats requiring connection to

transformer common terminal.

7. Continuous fan airflow can be increased by adding this jumper.

8. Set dip switches with power off per installation instructions

to set airflow and indoor fan off delays.

9. Optional humidistat is to be connected between R and BK. Factory

installed jumper R to BK on the circuit board must be cut if optional

humidistat is used. The jumper must also be cut when applying an airflow

command signal to the BK input such as with the variable speed single-zone

and multi-zone system controllers. On single speed cooling only/non-heat pump

systems, jumper Y to O for proper operation of the delay profiles and the humidistat.

For two compressor or two speed systems, jumper YLo to O.

W14

SEE

NOTE 6

From Dwg. B342025 Rev. 0

Y1/Ylo

W14 JUMPER

SEE NOTE 9

SEE

NOTE 7

B/C

B/C

TO 115 V 1 PH.,

60 HZ., POWER

SUPPLY PER

LOCAL CODES

HUM SEE

NOTE 5

EAC SEE

NOTE 5

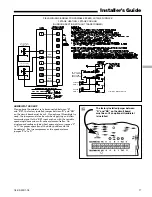

FIELD WIRING DIAGRAM FOR VARIABLE SPEED 2 STAGE FURNACE

2 STAGE HEATING

USING A 2 STAGE HEATING THERMOSTAT

NO COOLING