ES–412

2GR-FE ENGINE CONTROL SYSTEM

– SFI SYSTEM

ES

Components

Operations

Canister

Contains activated charcoal to absorb EVAP (Evaporative Emissions) generated in fuel tank.

Cut-off valve

Located in fuel tank. Valve floats and closes when fuel tank 100 % full.

Purge VSV (Vacuum

Switching Valve)

Opens or closes line between canister and intake manifold. ECM uses purge VSV to control EVAP purge flow. In order

to discharge EVAP absorbed by canister to intake manifold, ECM opens purge VSV. EVAP discharge volume to intake

manifold controlled by purge VSV duty cycle ratio (current-carrying time) (Open: ON; Closed: OFF).

Refueling valve

Controls EVAP pressure from fuel tank to canister. Valve consists of diaphragm, spring and restrictor (diameter: 0.08

inch). When fuel vapor and pressure inside fuel tank increase, valve opens. While EVAP purged, valve closes and

restrictor prevents large amount of vacuum from affecting pressure in fuel tank. Valve opened while refueling.

Roll-over valve

Located in fuel tank. Valve closed by its own weight when vehicle overturns to prevent fuel from spilling out.

Soak timer

Built into ECM. To ensure accurate EVAP monitor, measures 5 hours (+-15 min) after ignition switch turned off. This

allows fuel to cool down, stabilizing EVAP pressure. When approximately 5 hours elapsed, ECM in activated (refer to

fig. 3).

Canister pump

module

Consists of (a) to (d) below. Canister pump module cannot be disassembled.

(a) Vent valve

Vents and closes EVAP system. When ECM turns valve ON, EVAP system closed. When ECM turns valve off, EVAP

system vented. Negative pressure (vacuum) created in EVAP system to check for EVAP leaks by closing purge VSV,

turning on vent valve (closed) and operating leak detection pump (refer to fig. 1).

(b) Canister pressure

sensor

Indicates pressure as voltages. ECM supplies regulated 5 V to canister pressure sensor, and uses feedback from

sensor to monitor EVAP system pressure (refer to fig. 2).

(c) Leak detection

pump

Creates negative pressure (vacuum) in EVAP system for leak check.

(d) Reference orifice

Has opening with 0.02 inch diameter. Vacuum produced through orifice by closing purge VSV, turning off vent valve

and operating leak detection pump, to monitor reference pressure. Reference pressure indicates small leak of EVAP.

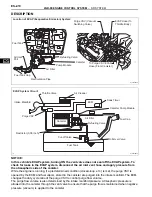

Canister Pump Module (fig. 1):

Canister

Canister Pressure

Sensor

Reference Orifice

(0.02 Inch)

: Airflow

Condition: Leak Check

From Refueling

Valve

Leak Detection

Pump: OFF

To Canister

Filter

(Atmosphere)

Leak Detection

Pump: ON

Condition: Purge Flow

Vent Valve: ON

(closed)

Vent Valve: OFF

(vent)

A115902E02

Summary of Contents for 2GR-FE

Page 176: ...ES 20 2GR FE ENGINE CONTROL SYSTEM SFI SYSTEM ES NEXT 20 CONDUCT CONFIRMATION TEST END ...

Page 247: ...2GR FE ENGINE CONTROL SYSTEM SFI SYSTEM ES 91 ES OK REPLACE ECM See page ES 518 ...

Page 412: ...ES 256 2GR FE ENGINE CONTROL SYSTEM SFI SYSTEM ES A END ...

Page 447: ...2GR FE ENGINE CONTROL SYSTEM SFI SYSTEM ES 291 ES OK REPLACE ECM See page ES 518 ...

Page 556: ...ES 400 2GR FE ENGINE CONTROL SYSTEM SFI SYSTEM ES A REPLACE TCM ...

Page 630: ...ES 474 2GR FE ENGINE CONTROL SYSTEM SFI SYSTEM ES OK REPLACE ECM See page ES 518 ...

Page 658: ...2GR FE ENGINE CONTROL SYSTEM VVT SENSOR ES 493 ES 22 INSTALL ENGINE UNDER COVER LH ...

Page 897: ...2GR FE STARTING SMART KEY SYSTEM ST 35 ST OK REPLACE MAIN BODY ECU ...

Page 923: ...2GR FE STARTING SMART KEY SYSTEM ST 61 ST OK REPLACE MAIN BODY ECU ...

Page 935: ...2GR FE STARTING SMART KEY SYSTEM ST 73 ST OK REPLACE MAIN BODY ECU ...

Page 940: ...ST 78 2GR FE STARTING SMART KEY SYSTEM ST OK REPLACE MAIN BODY ECU ...

Page 958: ...ST 96 2GR FE STARTING SMART KEY SYSTEM ST OK END MAIN BODY ECU DEFECTIVE ...