❍

8. Using a 1/4" x 1/4" x 36" balsa stick, make the Center

Stringer. Use medium CA to glue it into position. Using leftovers

saved from the assembly of the Fin and Stab, cut the center

supports and glue them into position. Position the center supports

as accurately as possible, as the installation of the formers as well

as the top and bottom of the fuse depends on their locations.

❍

9. Once the glue sets, remove the Fuselage Side from your

building surface. Examine and add thick CA glue to any open joints,

then use your sanding block or bar sander with medium (150-grit)

sandpaper to sand both sides of the Fuselage Side smooth.

❍

10. Place the Right Fuse Side underneath the wax paper. (The

side doesn’t have to align with the plans for this step.) The

doubler should be facing away from the wax paper or plan

protector. The remaining Fuse Side will be built directly on top of

our completed side to insure accuracy.

❍

11. Place the Left Fuse Side directly on top of the Right Fuse

Side, carefully aligning them together. Use T-pins to lock the two

sides together. Repeat the procedure for the Stabilizer Base.

❍

12. Make the Fuse Rails for the Left Fuse Side using the same

technique from the right side. The Left Fuse Side must match the

Right as closely as possible, or the fuselage will not be straight

when you are done. Once all the parts are cut and fit, use

Medium CA to glue them into position.

❍

13. Once the glue sets, remove the Left Fuselage Side from the Right

Fuselage Side. Examine and add thick CA glue to any open joints, then

use your sanding block or bar sander with medium (150-grit)

sandpaper to sand both sides of the Left Fuselage Side smooth.

❍

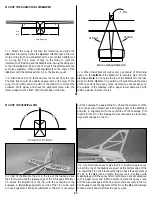

14. Locate the three fuselage triplers and glue them in their proper

locations on the inside of the fuselage. Make sure the alignment of

the triplers doesn’t interfere with the notches for the formers.

15

❍

15. Drill 1/4" holes as shown through the fuselage sides for the

wing dowels using the notches in the upper triplers for alignment.

Carefully sand the bottom edges of the fuselage sides flat to provide

a good surface to glue the bottom of the fuse into position.

Fuse Structure Assembly

❍

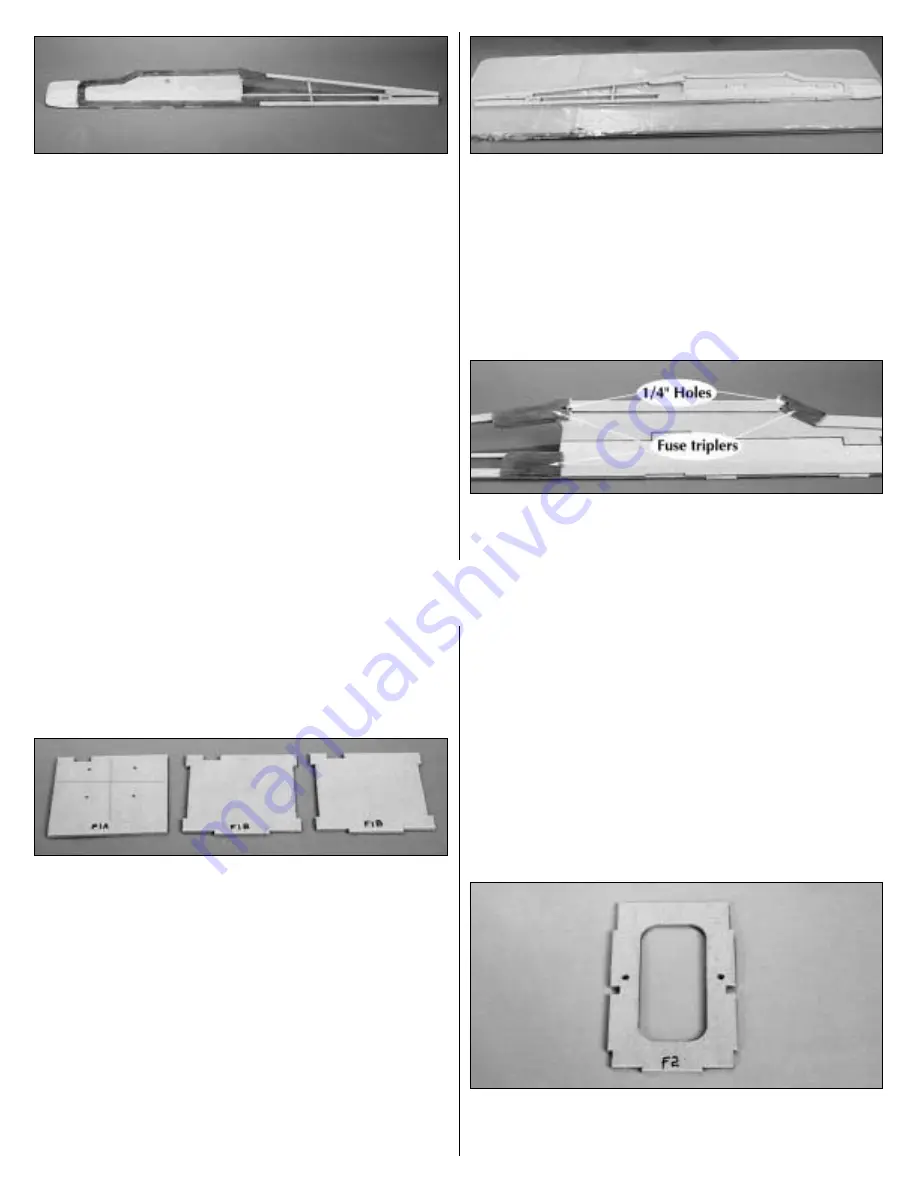

1. Locate the die-cut 1/8" plywood F1A Former and the two

die-cut 1/8" plywood F1B Formers. Center the F1A Former on the

F1B Formers with the punch marks visible. The notches of all

formers will align when positioned correctly. Use the plans to

position the formers. Use 30-minute epoxy to glue them together.

Clamp or tape the firewall formers together until the glue sets. You

should have used enough epoxy so it will "ooze" out between the

formers. This excess epoxy can be cleaned up before it cures using

a paper towel dampened with rubbing alcohol.

Note: For the following steps, refer to the firewall cross section

drawing on the fuselage plans. At this point you must know which

engine and mount you will use. If you are using the recommended

engine and mount, the punch marks on F1A will be in the correct

locations. If you are using a different engine or mount requiring

different bolt locations, you will need to determine the locations

for your installation. To determine the center of the mount, draw

lines on the firewall as shown on the plan and in the previous

photo. Position your engine mount so it is centered on the lines.

Mark the locations for your mounting bolts. Locations for the nose

gear and throttle pushrods will be determined the same way for

any engine/mount combination.

❍

2. If you are using the recommended mount, drill the four

punch marks in F1A with a 3/16" drill.

❍

3. Gently tap four 6-32 blind nuts into the back (F1B) side of

the firewall. Carefully apply a small drop of Thin CA to the

perimeter of the flange on each 6-32 blind nut.

❍

4. Locate the die-cut 1/8" plywood Former F2 and drill 3/16"

holes at the punch marks. Use the Former F2 cross section on the

fuselage plan sheet to confirm these locations.

16