CAUTION!!!: You must use extreme care when cutting hinge

slots with a hobby knife, to avoid cutting yourself! If the balsa

part breaks while you are pushing on the knife, the blade could

go into your hand before you know it! A good precaution is to

wear leather gloves while performing the following steps and

always cut AWAY from yourself.

❍

3. Insert the hinges into the slots and trial fit the Rudder and

Elevator in place on the Fin and Stabilizer. Do not glue the

hinges until after you have covered the model.

BUILD THE FUSELAGE

Fuse Side Construction

❍

1. Cut the "Fuselage side view" section from the fuselage plan

sheet and tape it on your building board. Tape a piece of Top Flite

Plan Protector or wax paper over the plan.

❍

2. Glue the balsa die-cut 1/8" Upper Forward Fuse Sides to the

balsa die-cut 1/8" Lower Forward Fuse Sides using thin CA. Mark

the inside surface of the fuse sides with the letters 'R' and 'L' to

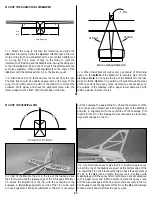

C. Trial fit the hinge into the slot. If the hinge is difficult to

push in, re-insert the knife and move it back and forth in

the slot a few times to enlarge the slot.

★★★★

Pro Tip: Hinge slotting is a procedure that is required

for every model airplane. We have found that the technique

described below is accurate and fairly easy. Just work slowly

and carefully. Remember: Hobby knives are extremely sharp!

A. Begin by carefully cutting a very shallow slit at the hinge

location. This first cut is to establish your cut in the right

place, so concentrate on staying on the centerline and

don't cut too deep!

B. Make three or four more cuts in the same line, going slightly

deeper each time. As you make these additional cuts, work

on going straight into the wood. Continue this process

while "wiggling" the knife handle back and forth until the

blade has reached the proper depth for the hinge.

13

designate the inside of the Right and Left fuselage sides. Be sure

to make a RIGHT and a LEFT fuselage side. Sand both sides of

the fuse sides using 150-grit sandpaper.

❍

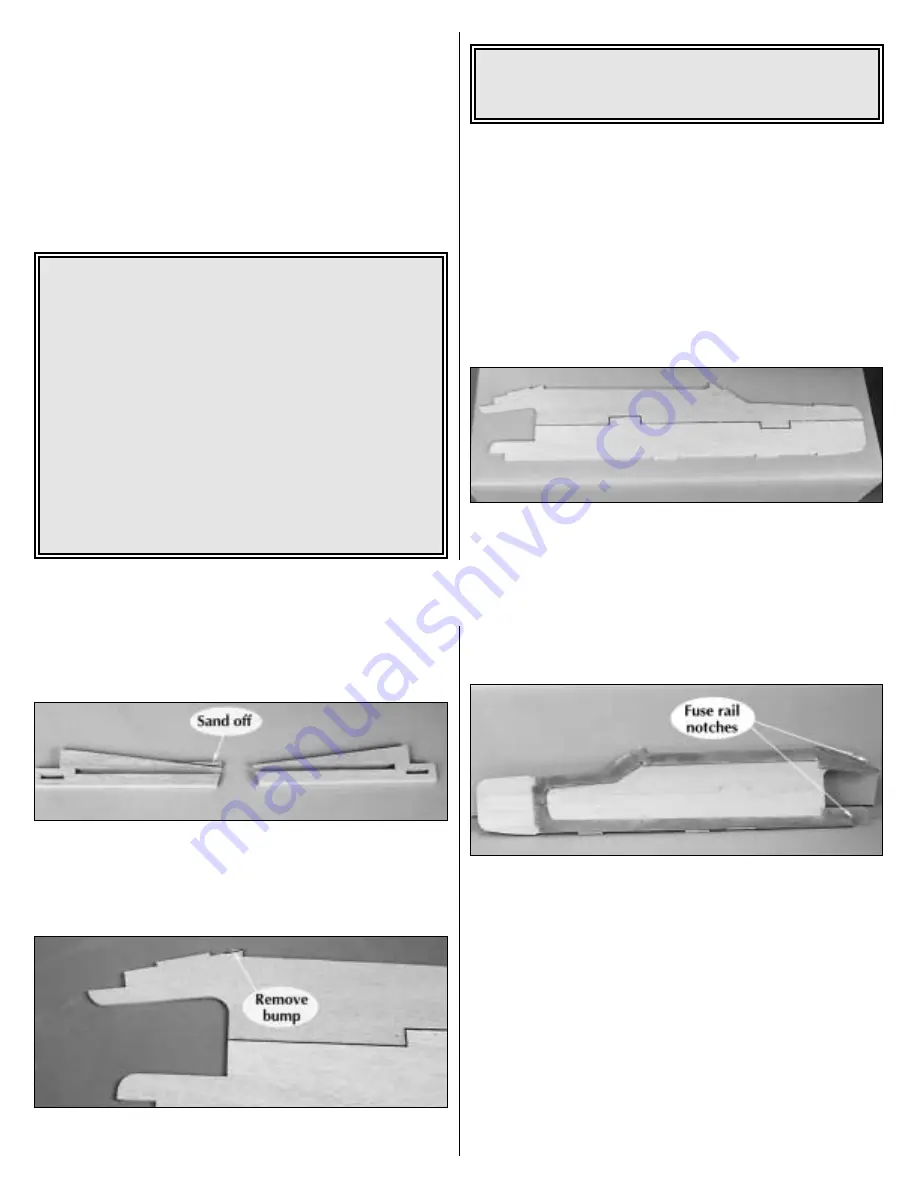

3. Locate the four die-cut 1/8" balsa Stabilizer Bases. Carefully

align and laminate two of the bases together using medium CA to

produce a 1/4" thick base. Repeat the procedure for the

remaining two bases. Sand the area shown in the photo using

120-grit sandpaper.

❍

4. Use a straightedge to mark a line along the top of both fuse

sides, as there is a slight bump necessary for the die-cutting of the

part. Use a hobby knife and/or bar sander to remove the bump.

(This bump is also on the upper fuse doubler.)

❍

5. Locate the die-cut 1/8" plywood Upper and Lower Fuse

Doublers. Make sure you are making both a Left and Right fuse

side. Test fit them onto the fuse sides as shown in the photo. Make

any necessary adjustment to allow the doublers to fit accurately

onto the fuse sides. Once all the fitting is done, glue them in

position using Thin CA. Make sure to make both a left and right

set. Sand the notches for the balsa fuse rails to provide a smooth

glue surface.

❍

6. Place the Right Fuse Side onto the fuselage plan and pin it

in position. (The doubler should be facing away from the plan

sheet). Pin the Stabilizer Base into position on the plans.

❍

7. Use two of the 1/4"x 1/2" x 24" balsa sticks to make the upper

and lower Fuse Rails. Use medium CA to glue them into position.

Trim the excess extending past the Stabilizer Base.

14