9

Some medium CA glues can be slow to set, especially when used to

fill gaps. A product known as CA Accelerator is available to speed

up the curing process. It is sprayed onto the joint after the glue is

applied and chemically reacts with the glue, causing it to set very

rapidly. There are a few precautions when using an accelerator...

Use it in a well-ventilated area. The rapid reaction can release

irritating fumes at a much higher rate than normal. Do not use

CA accelerators with thin CA!

Be careful when using the accelerator around plastics. Certain

accelerators will attack plastics and the vapors may fog clear

canopies. It is best to test the glue and accelerator on a leftover

piece of plastic if one is available.

Using too much accelerator may cause the CA glue to react very

rapidly and literally boil. This will result in a joint with a chalky

white color which is not nearly as strong as a normal joint.

Epoxy is used on high-stress joints requiring strength and vibration

resistance. Epoxy also works well in areas encountering fuel. The

slower cure time allows parts to be clamped, checked and

realigned if necessary before it cures. Epoxy is available in many

different formulas having different cure times. The single best type

of epoxy to have when building your Tower Trainer 40 is one

which sets up in 30 minutes, but you may also find 6-minute

epoxy handy to have around.

NOTES ON SANDING

Use a block or bar sander whenever possible. The flat block will

“ignore” glue and variations in wood hardness and give you a

true and even shape.

Always use fresh, sharp sandpaper. Sharp sandpaper will cut

through glue and hard materials easily, giving an even surface.

Older, dull sandpaper will require more pressure and may gouge

the surface. Now on to building your Tower Trainer 40!

“BUILD THE TAIL SURFACES”

Build the Stabilizer and Elevator

❍

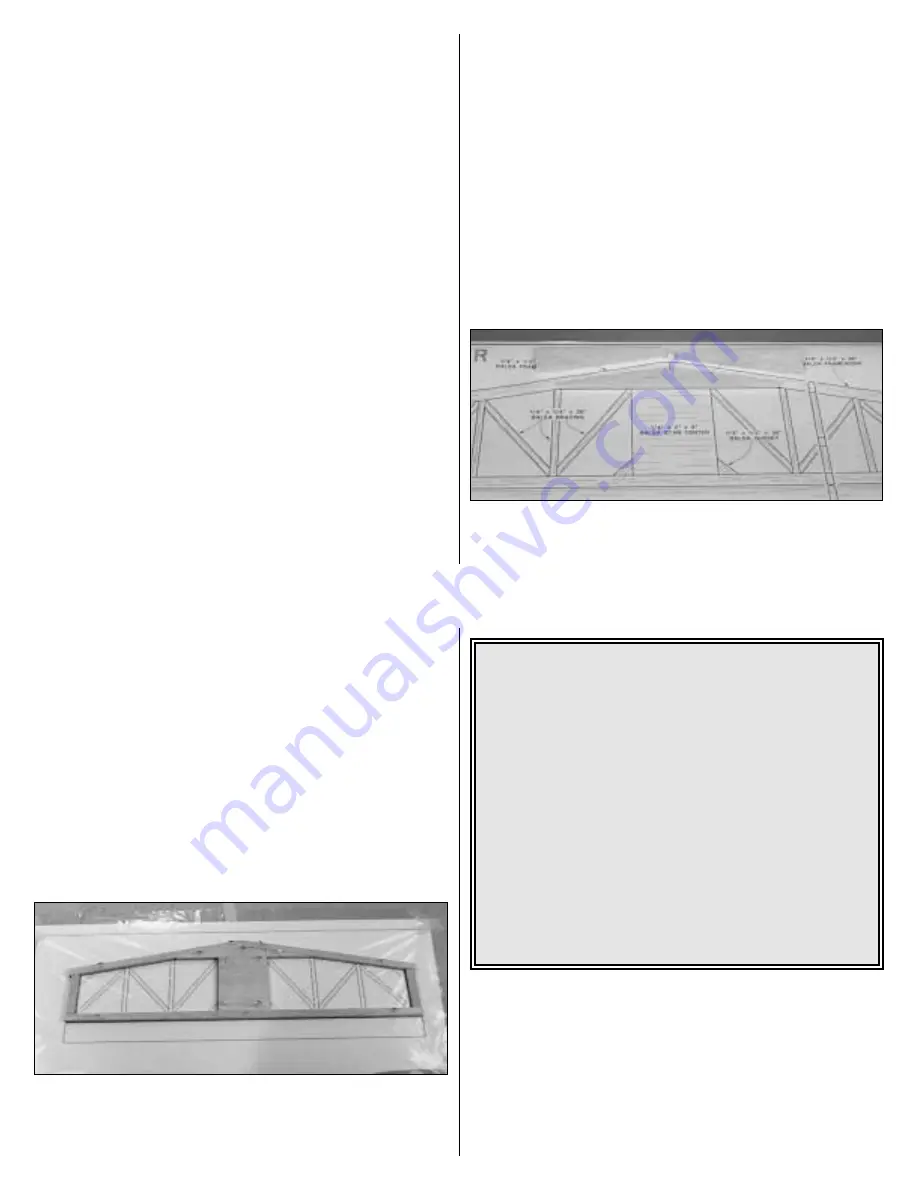

1. Cut the "Stabilizer/Elevator" section from the fuselage plan

sheet and tape it on your building board. Tape a piece of wax

paper or Plan Protector over the plan.

10

❍

2. Place the 1/4" x 1" x 10" balsa stick over the portion of the

plan marked "Stab Forward Center," and line up the back edge of

the stick with the straight line. Draw two angled lines where you

will cut this stick. Remove the stick from the plan and cut the

stick along the lines using a hobby knife or razor saw. Straighten

and square the cut edges with a sanding block. Trim the ends

slightly to match the length shown on the plans.

❍

3. Pin the Stab Forward Center into position on the plans. Test

fit the balsa 1/4" x 3" x 4" Stab Center into place. There should

be no gaps between the center and forward pieces. After fitting,

glue and pin the center to the forward using Medium CA.

❍

4. Use two 1/4" x 1/2" x 36" balsa sticks to build the outside

framework of the Stabilizer. Start by placing the longest piece

first, working until you are placing the shortest (end) pieces. Glue

each piece together using Medium CA as you proceed.

❍

5. Cut the corner gussets from the 1/4" x 1/2" balsa stick and

glue them into position.

★★★★

Pro Tip: If you are unfamiliar with "Built-up"

construction, we have found that the following method is

very easy and accurate.

A. Position an uncut stick directly over the plan and pin it

in place.

B. Mark each side of the stick where it ends or butts with

another part.

C. Remove the stick from the building surface and flip it over.

Draw a line between the marks you made previously using

a straight edge.

D. Using a razor saw, cut as close to the line as possible. Then,

with your sanding block, true-up the ends to the line. Flip

the part over and pin back in place over the plan.