Item

7

. Air outlet

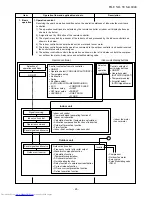

Operation flow and applicable data,etc

Description

selection

< How to change air outlet selection >

1. Operate the air conditioner and select cooling or heating

mode.

(Air outlet selection can't be changed at standby mode.)

•

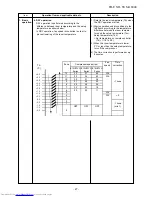

In Cooling operation, only lower-flow

can't be selected.

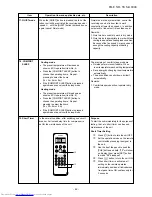

2. Push AIR OUTLET SELECT button on the unit operation

panel to change air outlet selection.

1. Purpose

2. Description

•

In Dry mode operation,bi-flow and

lower-flow can't be selected.

•

In heating operation and bi-flow

setting, the air outlet is set only upper

flow for preventing cold draft when

the indoor heat exchanger sensor

temperature (TC) is lower than 33

degrees.

•

In cooling operation and bi-flow

setting, the air outlet is set only upper

flow for pravinting the room from

overcooling when the room

temperature (TA) is nearing the setup

temperature.

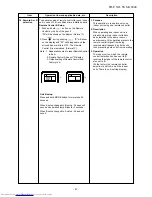

This function can be cancelled to

AIR OUTLET SELECT button

AIR OUTLET indication

Air outlet is contorolled as below.

< How to cancel to change upper-flow at Bi-flow setting in cooling >

1. Stop operation.

2. Push and hold AIR OUTLET SELECT button on the unit

operation panel over 10seconds (less than 20seconds).

AIR OUTLET SELECT button

3. After holding 10seconds, 4 beep sounds in heard and

TEMPERATURE indicator displays "1" for 5seconds.

Release AIR OUTLET SELECT button.

change setting.

FILE NO. SVM-18048

- 33 -