Lubrication

Greasing the Bearings

Service Interval:

Every 25 hours—Grease all the lubrication

points.

Grease Type:

No. 2 General Purpose, Lithium-Base Grease

1.

Park the machine on a level surface, and disengage the

blade-control switch.

2.

Move the motion-control levers outward to the park

position, stop the engine, remove the key, and wait for

all moving parts to stop before leaving the operating

position.

3.

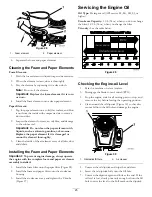

Clean the grease fittings (Figure 25 and Figure 26) with

a rag.

Note:

Make sure to scrape any paint off of the front

of the fitting(s).

1

G014522

Figure 25

1.

Front caster tire

Figure 26

Located on the seat-pan underside

1.

Read the instructions

before servicing or

performing maintenance

3.

Grease every 25 operating

hours

2.

Check the tire pressure

every 25 operating hours

4.

Engine

4.

Connect a grease gun to each fitting (Figure 25 and

Figure 26).

5.

Pump grease into the fittings until grease begins to

ooze out of the bearings.

Engine Maintenance

Servicing the Air Cleaner

Service Interval:

Before each use or daily—Clean and check

the air cleaner foam element.

Every 50 hours—Replace the air cleaner paper

element.

Note:

Service the air cleaner more frequently if the operating

conditions are extremely dusty or sandy.

Removing the Foam and Paper

Elements

1.

Disengage the blade-control switch (PTO).

2.

Stop the engine, wait for all moving parts to stop, and

remove the key before leaving the operating position.

3.

Clean around the air cleaner to prevent dirt from

getting into the engine and causing damage.

4.

Remove the air-cleaner cover by unscrewing the 2

knobs (Figure 27).

G017862

Figure 27

1.

Air-cleaner cover

2.

Knobs

5.

Carefully remove the foam and paper filter elements

from the air-cleaner housing (Figure 28).

24

Summary of Contents for TimeCutter SS 3216

Page 44: ...Schematics G014644 Electrical Diagram Rev A 44 ...

Page 45: ...Notes 45 ...

Page 46: ...Notes 46 ...

Page 47: ...Notes 47 ...