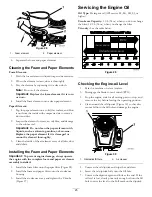

Figure 28

1.

Foam element

2.

Paper element

6.

Separate the foam and paper elements.

Cleaning the Foam and Paper Elements

Foam Element:

1.

Wash the foam element in liquid soap and warm water.

2.

When the element is clean, rinse it thoroughly.

3.

Dry the element by squeezing it in a clean cloth.

Note:

Do not oil the element.

Important:

Replace the foam element if it is torn

or worn.

4.

Install the foam element onto a clean paper element.

Paper Element:

1.

Tap the paper element on a solid, flat surface, and blow

it out from the inside with compressed air to remove

dust and dirt.

2.

Inspect the element for tears, an oily film, and damage

to the rubber seal.

Important:

Do not clean the paper element with

liquids, such as solvents, gasoline, or kerosene.

Replace the paper element if it is damaged or

cannot be cleaned thoroughly.

3.

Clean the inside of the air-cleaner cover of all dirt, dust,

and debris.

Installing the Foam and Paper Elements

Important:

To prevent engine damage, always operate

the engine with the complete foam and paper air cleaner

assembly installed.

1.

Install the foam filter onto the paper filter (Figure 28).

2.

Install the foam and paper filter onto the air-cleaner

housing.

3.

Install the air-cleaner cover, and tighten the 2 knobs

(Figure 27).

Servicing the Engine Oil

Oil Type:

Detergent oil (API service SF, SG, SH, SJ, or

higher)

Crankcase Capacity:

1.0 L (34 oz) when you do not change

the filter; 1.05 L (36 oz) when you change the filter.

Viscosity:

See the table below.

Figure 29

Checking the Engine-oil Level

1.

Park the machine on a level surface.

2.

Disengage the blade-control switch (PTO).

3.

Stop the engine, wait for all moving parts to stop, and

remove the key before leaving the operating position.

4.

Clean around the oil dipstick (Figure 30) so that dirt

cannot fall into the fill hole and damage the engine.

G017863

2

Figure 30

1.

Oil dipstick/fill hole

2.

Air cleaner

5.

Unscrew the oil dipstick and wipe the end clean.

6.

Screw the oil dipstick fully onto the fill hole.

7.

Unscrew the dipstick again and look at the end. If the

oil level is low, slowly pour only enough oil into the fill

hole to raise the level to the Full mark on the dipstick.

25

Summary of Contents for TimeCutter SS 3216

Page 44: ...Schematics G014644 Electrical Diagram Rev A 44 ...

Page 45: ...Notes 45 ...

Page 46: ...Notes 46 ...

Page 47: ...Notes 47 ...