12.1 Explanations and countermeasures for error messages

12-3

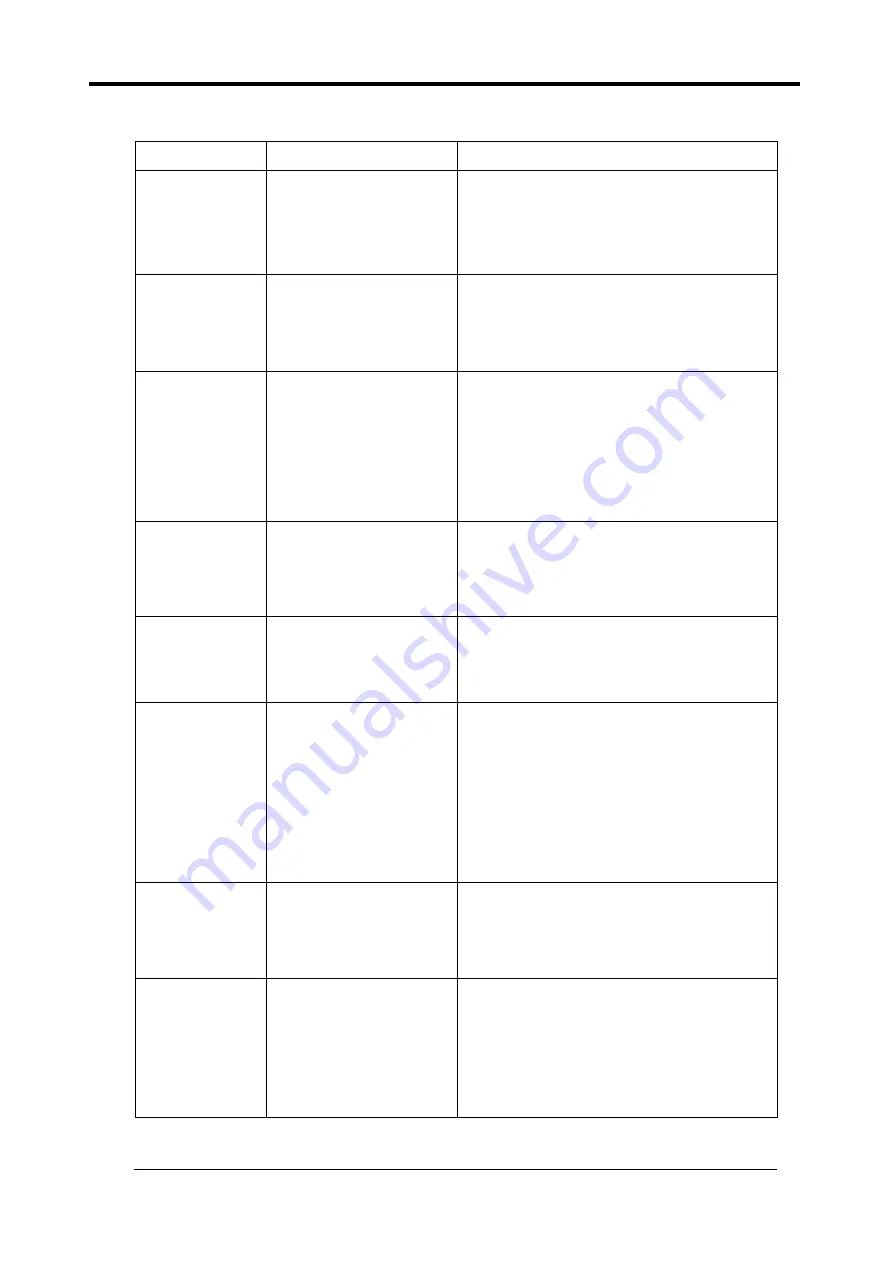

Error classification

Error message

Explanations and countermeasures

CF card error

This message is indicated when recording to

data memory is set On while CF card is not

inserted. Insert a CF card or set Off for the

recording to data memory. Refer to

“6.3 CF

card

” about the operation for recording.

CF card error

This message is indicated when no enough

capacity is left in the CF card. Delete

unnecessary data to secure CF card capacity.

Refer to “6.3 CF card” for the operation of

data memory.

Data memory/

CF card error

This message is indicated when no enough

capacity is left in the data memory and CF

card. Delete unnecessary data to secure

data memory and CF card capacity.

Refer to “6.2 Data memory” for the operation

of data memory.

Refer to “6.3 CF card” for the operation of CF

card.

Input value error

This message is indicated when the input

value is out of the settable range.

For example, settable range for interval timer

is 1s

~

99h 59m 59s. This message appears

if a value exceeding this range is input.

ADC error

Failure in A/D conversion circuit and/or

communication circuit may have occurred.

Contact TML or your local representative

Time out error

This message is indicated when RS-232C

communication is not performed. If you do

not use data output to RS-232C, set Off for

data output.

Refer to

“7.3 Data output” for the way of

setting data output.

When using RS-232C for data output, set the

same Flow control as the external device.

Refer to

“7.2 RS-232C setting” for the way of

setting flow control.

This message is indicated when interval

measurement is started without setting

interval timer program. Set interval timer.

Refer to

“5.8 Automatic measurement” for the

way of setting interval timer program.

This message is indicated when you tried to

turn off the power while next step of automatic

measurement

is

scheduled

within

30

seconds. To turn off the power, stop the

automatic measurement.

Refer to

“5.8 Automatic measurement” for the

operating method of automatic measurement.

Summary of Contents for TC-32K

Page 1: ...O p e r a t i o n M a n u a l TC 32K HANDHELD DATA LOGGER...

Page 8: ...Chapter 12 Error Message 12 1 Explanations and countermeasures for error messages 12 2...

Page 9: ...Chapter 1 Overview 1 1 Overview 1 2 1 2 Features 1 2 1 3 Details about each part 1 3...

Page 22: ...2 5 Operation outline 2 10 memo...

Page 23: ...Chapter 3 Sensor Connection 3 1 Sensor connection 3 2...

Page 65: ...5 10 Measurement auxiliary setting 5 28 memo...

Page 78: ...6 5 Recording in data memory and CF card 6 13 memo...

Page 86: ...7 7 Remote measurement 7 8 memo...

Page 98: ...8 7 Factory setting 8 12 memo...

Page 127: ...11 4 Outside drawing 11 8 11 4 Outside drawing Unit mm...

Page 128: ...Chapter 12 Error Message 12 1 Explanations and countermeasures for error messages 12 2...