5. Inspection and Maintenance

CAUTION

Parts Inspection Procedure

Gaskets

Bellows

Valve Seat

Valve Plug

Body Interior

Check for warping and damage

Check for cracking, warping or other damage

Check for build-up, scratches or wear

Check for build-up, scratches or wear

Check for build-up or scale

When parts have been removed, or during periodic inspections, use the following table to inspect

the parts and replace any that are found to be defective.

• Installation, inspection, maintenance, repairs, disassembly, adjustment

and valve.

opening/closing should be carried out only by trained maintenance

personnel.

• Take measures to prevent people from coming into direct contact with

product outlets.

• Install for use under conditions in which no freeze-up will occur.

1 N

•

m

≈

10 kg

•

cm

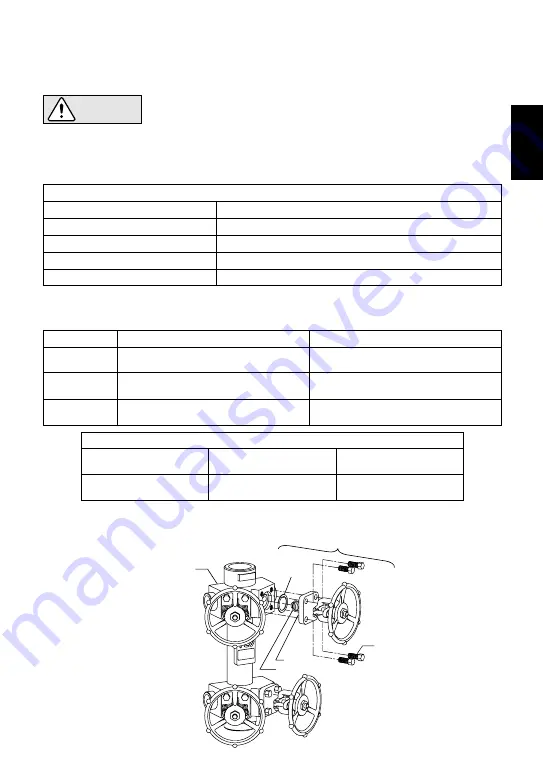

Use the following procedures to remove components. Use the same procedures in reverse to

reassemble.

Note: - Coat all threaded portions with anti-seize.

- If drawings or other special documentation were supplied for the product, any torque given

there takes precedince over values shown here.

Bonnet Bolt

Valve Unit

Bonnet Gasket

Remove with a 12 mm ( ") socket

wrench

Coat threads with anti-seize; tighten to

the proper torque

Insert the valve plug into the body, being

careful not to scratch or dent the bellows

Replace with a new gasket

Pull straight out being careful not to scratch

the valve plug or scratch or dent the bellows

Clean being careful not to scratch the

surface of the body seat

During Disassembly

Part

During Reassembly

Torque

N·m (lbf·ft)

60 (44)

12 ( )

Distance Across Flats

mm (in)

Tightening Torque

Part Name

Bonnet Bolt

32

15

/

32

15

/

Body

Lower

Bonnet Gasket

Valve Unit

Bellows

Valve Plug

Bonnet Bolt

English

― 8 ―

Summary of Contents for M12

Page 19: ... 18 ...

Page 26: ... 25 ...