4. Proper Installation

CAUTION

• Installation, inspection, maintenance, repairs, disassembly, adjustment

and valve opening/closing should be carried out only by trained

maintenance personnel.

• Take measures to prevent people from coming into direct contact with

product outlets.

• Install for use under conditions in which no freeze-up will occur.

• Install for use under conditions in which no water hammer will occur.

1. Before installing the product, blow out the inlet

piping to remove any piping scraps, dirt and oil.

Close the inlet valve after blowdown.

2. Before installation, be sure to remove all

protective seals.

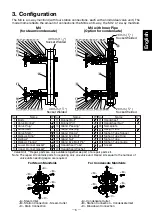

3. Prepare a mounting stand. The mounting stand

should be less than 160mm (6 ") wide (the

face to face distance between station

connections). If a wider mounting stand is used,

it may interfere with any steam trap station

connected to the manifold.

4. Using M12 threaded bolts, attach the manifold

to the mounting stand (figure 1). Install the

manifold vertically with the raised “TLV”

lettering on the body right-side up and

horizontal.

Note

: If the manifold is to be mounted in some way other than as described here, be sure to

consider and secure sufficient space for the installation, operation and maintenance of

required steam traps and valves.

5. Complete the installation by installing the required steam traps and valves. For steam

applications, install a stop valve at the steam inlet, and a steam trap and stop valve at the drain

connection. For condensate applications, install stop valves at the condensate outlet and

blowdown connections, and a trap station with a trap unit or a steam trap and stop valve at

each station connection. For the proper installation of trap stations, steam traps and/or valves,

refer to the separate instruction manuals of each product.

6. Open the inlet and the outlet valves and verify proper operation. If there is a problem,

determine the cause using the “Troubleshooting” section in this manual.

16

5

/

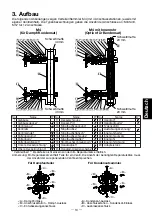

Note for Screwed Connections

: There may be clearance problems when installing traps and

valves with threaded connections. To prevent any obstructions, such as valve handles contacting

products installed on lines above or below, offset each line slightly. Install all short lines first, then

longer lines (figure 2). Offsetting lines is not necessary when installing products with socket

welded connections.

Mounting

Stand

M12 Thread Bolt

& Nut

16

5

/

160 mm

(6 ")

Figure 1

Mounting Stand

Width

Install short lines first

Install long lines last

Figure 2

English

― 7 ―

Summary of Contents for M12

Page 19: ... 18 ...

Page 26: ... 25 ...