Thermo Fisher Scientific CryoExtra CE8100 Series

Preventative Maintenance | 63

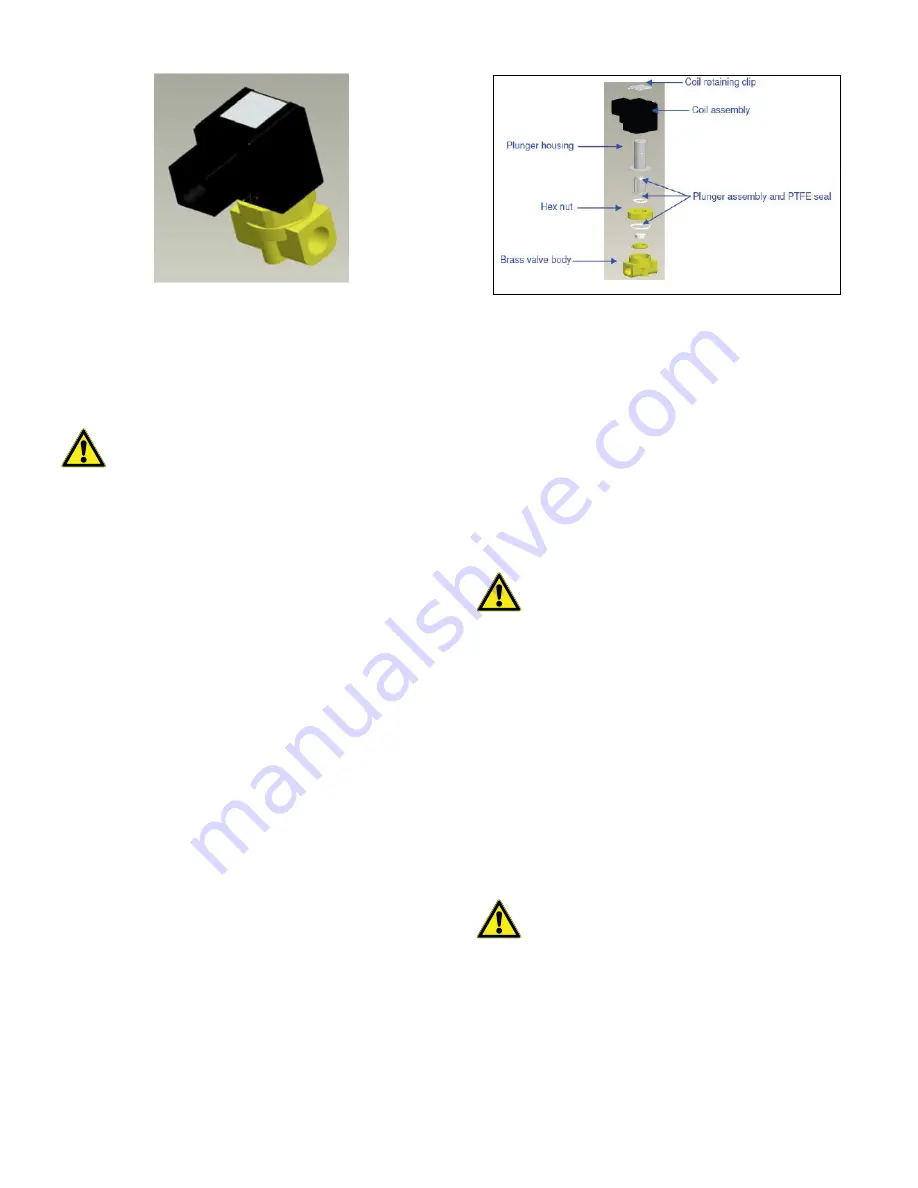

Figure 17. SMC Solenoid Valve (Current

Production)

SMC (black) Solenoid Valve Replacement

1. Remove plumbing shroud to gain access to plumbing

system.

2. Remove coil retaining clip by inserting a flathead

screwdriver between the clip and the edge of the coil

body. Twist the screwdriver and the clip should slide off.

3. Remove and discard the coil assembly.

4. Using a crescent wrench loosen hex nut and remove the

plunger housing. Remove plunger housing and plunger

assembly. Discard these parts.

5. Remove any debris that may have collected in brass

valve body.

6. Inspect the brass valve body of the solenoid valve for

nicks or damage. If the sealing surface appears to be in

good condition, the valve body may be reused. If the

sealing surface is damaged, the plumbing will need to be

disassembled and the entire body will need to be

replaced (this is not common).

7. Disassemble a new SMC valve (PN 14224611S) using

the above procedure.

8. Install the new plunger, plunger housing and coil

assembly onto the old valve body.

9. Assembly valve with new components in the reverse

order.

10. Verify that no leaks are present using leak detect solution.

11. Open the LN

2

supply valve and initiate a fill cycle by

pressing “Fill Start’. Allow the fill cycle to complete and

verify that flow stops at the termination of the fill cycle.

Note:

If the brass valve body requires replacing, the freezer

plumbing will need to be disassembled and the entire valve

replaced (PN 14224611S). It is typically easier to start

disassembling the plumbing assembly beginning at the fill tee

for fill valve replacement or the gas bypass muffler for gas

bypass valve replacement.

Note:

When installing a complete new valve, ensure it is

oriented correctly. An “N” is engraved on the side of the SMC

brass valve body. The valve should be installed so that this “N”

is on the inlet side of the valve.

Relief Valve Replacement

1. Remove plumbing shroud to gain access to plumbing

system.

2. If equipped with a relief valve deflector, loosen the

deflector clamp and slide off the deflector.

3. Loosen the relief valve and remove it from the plumbing

assembly. Be sure to support the attachment tube with

wrench to prevent damage from twisting.

4. Install new relief valve (PN 1810032) applying new. Teflon

tape if needed. Ensure relief valve is rated to 50 PSI (3.4

bar).

CAUTION :

Ensure that the LN

2

supply valve is

closed and the plumbing assembly is vented

before removing the solenoid valves.

CAUTION :

Ensure that the LN

2

supply valve is

closed and the plumbing assembly is vented

before removing the relief valve.

CAUTION :

Installing a relief valve with a different

pressure rating could prevent proper operation

and lead to a dangerous over pressurized

condition.