4

b.

Non-combustible material:

“...material that is not capable of being ignited and burned; such as material

consisting entirely of, or a combination of, steel, iron, brick, concrete, slate,

asbestos, glass, and plaster.”

:

Carefully read and thoroughly understand the following guidelines and warnings

before continuing with the installation of this appliance. Failure to follow these guidelines can

cause improper and unsafe operation of this appliance. Unsafe operation can result in substantial

property damage, severe personal injury, or death.

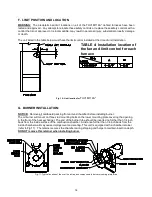

1. This appliance shall be used with only the type of fuel oil for which it is approved. Refer to the

appliance-rating label for the required type of fuel.

2. This appliance is an oil-fired furnace designed for installation on non-combustible materials. This

appliance is also approved for attic installation on non-combustible materials.

3. Ensure that adequate combustion and ventilation air is available to the unit.

4. The airflow resistance of the duct system attached to this appliance must fall within the allowable

external static pressure range for this unit. Refer to the

Airflow Requirements and Sizing of

Ductwork

section of this manual.

5. Make sure supply and return air ducts are completely sealed to the appliance casing. Refer to the

Airflow Requirements and Sizing of Ductwork

section of this manual.

NOTE:

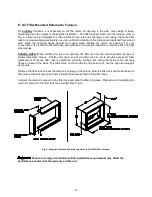

The THV1M119A* furnace is approved for closet installation. The THV1M119A* requires two

openings in the closet door, each having a minimum area of 181 sq. inches. This free area intentionally

exceeds the recommended minimum free area of 1 square inch per 1000 BTUH of input rate.

Fig 1: Properly Positioned Combustion Air Openings In Walls (Fig. 1A) and Doors (Fig. 1B).

B. MAKE-UP AIR:

Today's emphasis on home insulation increases the probability of inadequate air

supply to the furnace. Heavy insulation cuts off infiltration of outside air, which previously replaced inside

air removed by bathroom, kitchen and laundry vent fans, and air escaping up chimneys. This causes a

negative pressure differential within the home that reduces the supply of air available to the furnace for

combustion and ventilation.

The THV1M119A* Make-Up-Air Control, installs quickly and easily on any warm air heating system,

delivers controlled, fresh air automatically during the winter and a constant supply of clean, fresh air for

comfortable summer living. It resolves the negative pressure differential problem.

Summary of Contents for THV1M119A960SA

Page 2: ......

Page 4: ......

Page 6: ...2...

Page 36: ...32 V Sequence of Operations Flow Chart...

Page 37: ...33...

Page 38: ...34 VI Trouble Shooting Flow Chart...

Page 39: ...35...

Page 40: ...36...

Page 41: ...37...

Page 42: ...38...

Page 44: ...40 Appendix A Replacement Parts for THV1M119A...

Page 45: ...41...

Page 46: ...42 Appendix B THV1M119A960SA PSC Wiring Diagram...