9

Fig. 7: Alternate constructions that allow reduced clearances to combustible materials.

REDUCTION OF CLEARANCES WITH SPECIFIED FORMS OF PROTECTION:

Type of protection applied to and covering all surfaces of combustible material within the distance

specified as the required clearance with no protection unless otherwise noted, all dimensions in inches,

refer to Fig. 7.

Required clearance with no protection from the appliance or

chimney connector is:

18 inches

9 inches

6 inches

Sides &

Sides &

Sides &

Above Rear

Above Rear

Rear

a. 3-1/2" thick masonry wall without ventilation air space….

-- 12

-- 6

-- 5

b. 1/2" insulation board over 1" glass fiber or mineral wool batts…

12 9

6 5

4 3

c. 0.024(24 gauge) sheet metal over 1" glass fiber or mineral

wool batts reinforced with wire on rear face with ventilated air

space…

9 6

5 3

3 3

d. 3- 1/2" thick masonry wall with ventilation air space..

-- 6

-- 6

-- 6

e. 0.024 (24 gauge) sheet metal with ventilated air space.

9 6

5 3

3 2

f. 1/2" thick insulation board with ventilation air space..

9 6

5 3

3 3

g. 0.024 ( 24 gauge) sheet metal with ventilated air space over

0.024 (24 gauge) sheet metal with ventilated air space….

9 6

5 3

3 3

h. 1" glass fiber or mineral wool batts sandwiched between two

sheets 0.024 (24 gauge) sheet metal with ventilated air space

9 6

5 3

3 3

A. Equal the required clearance with no protection.

B. Equals the reduced clearance permitted in accordance with the preceding clearance chart.

C. The protection applied to the construction that covers the combustible material should extend far enough

in each direction to make C equal to A.

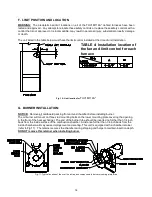

The vent connector pipe between the furnace and chimney shall be of equal diameter as the flue outlet of the

furnace.

The vent connector pipe must be made of 24 gauge (or thicker) corrosion-resistant steel.

The

vent connector pipe should be as short as possible and installed so that it has a continuous rise from the

furnace to the chimney. The horizontal length of a connector to a natural draft chimney or vent serving a single

appliance shall not be more than 75 percent of the height of the vertical portion of the chimney or vent above

the connector. Elbows should be minimized and the pipe should be joined with metal screws and supported by

straps. All horizontal runs of vent connector pipe should be pitched upward a minimum of ¼ inch per foot of run.

A thimble should be used to connect the vent connector pipe to the chimney so the pipe may be readily

removed in case of inspection or replacement. See Fig. 6 on preceding page.

Summary of Contents for THV1M119A960SA

Page 2: ......

Page 4: ......

Page 6: ...2...

Page 36: ...32 V Sequence of Operations Flow Chart...

Page 37: ...33...

Page 38: ...34 VI Trouble Shooting Flow Chart...

Page 39: ...35...

Page 40: ...36...

Page 41: ...37...

Page 42: ...38...

Page 44: ...40 Appendix A Replacement Parts for THV1M119A...

Page 45: ...41...

Page 46: ...42 Appendix B THV1M119A960SA PSC Wiring Diagram...