GB-14

RANSOMES G PLEX II Series :WD

MAINTENANCE AND PARTS MANUAL

GB

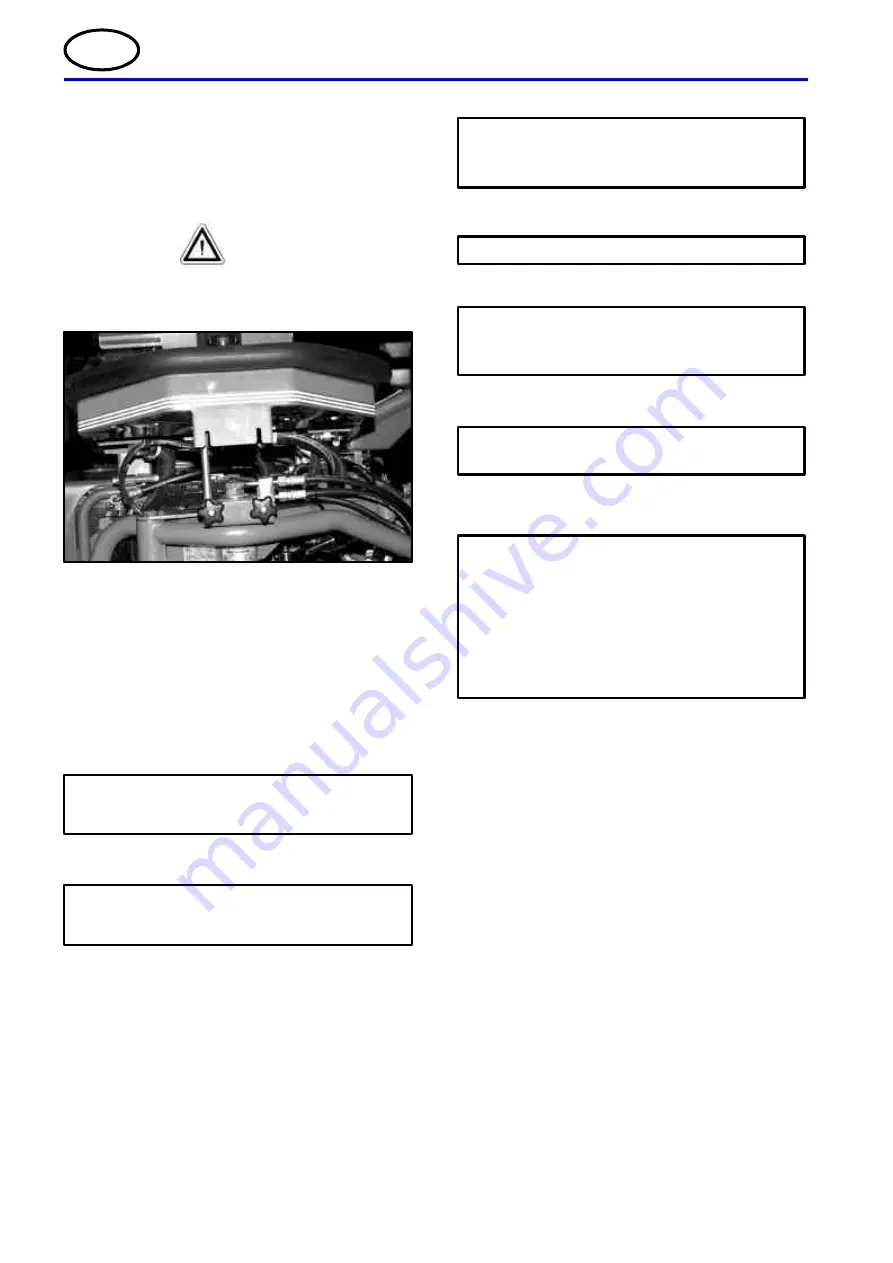

ENGINE ACCESS

The rear section of the unit can be raised for better

access to the engine. Loosen the two handknobs

above the rear fork. Raise the fuel tank frame.

Support it by pivoting the rod beneath the fuel tank

down and securing it in the cup next to the fork pivot

(See Fig. 27).

WARNING

•

DO NOT

remove the fuel tank cap while

the tank is in the raised position.

Figure 27

Rear Section of Unit Raised

MAINTENANCE GUIDE

The following maintenance charts have been

compiled as a general guideline for service

intervals, based on hours of operation. Refer to the

engine manual for further maintenance information.

AS REQUIRED

Replace air cleaner element

Gas: refer to the engine operator's manual

Diesel: refer to Air Cleaner section on page 17

DIESEL ENGINE OIL

Change engine oil and filter after the first 50 hours.

Then every 100 hours of operation or yearly, whichev

er comes first.

NOTICE

•

Depending on operating conditions, the

engine oil and oil filter may need more

frequent replacement to maintain engine

performance and help prevent

unnecessary repairs.

FIRST 35 HOURS

Check for loose parts

Check valve clearance

Check idle speed

EVERY 25 HOURS OR WEEKLY

Lubricate all lubrication fittings (refer to Lube Chart)

EVERY 75 HOURS

Check tire pressure (with low pressure tire gauge)

Change fuel filters (diesel only)

Check for loose parts

EVERY 200 HOURS

Check valve clearance and adjust as required

Change hydraulic oil and filter

EVERY 600 HOURS (OR YEARLY)

Perform previous services

Replace primary (large) fuel filter cartridge

Check starter motor brushes

Check all belts and hoses, replace as required

Clean battery terminals

Diesel:

Drain and replace engine coolant

Check glow plugs

Check injection pump and timing

BACKLAPPING

Routine backlapping will help keep cutting blades

sharp and increase reel life and

performance. Backlapping frequency

depends on many variables, but should be

performed frequently as normal

maintenance. Refer to the backlapping

procedure located on page 19 of this

manual.

ENGINE OIL LEVEL

Damage to engines due to improper maintenance or

use of incorrect oil quality and/or viscosity is not

covered by the engine warranty (refer to the engine

operator’s manual for crankcase capacity and

recommended oil grade and weight).

Unit must be on a level surface to obtain an

accurate oil level reading.

The oil level must be kept between the two marks

on the dipstick.

Summary of Contents for D722B

Page 2: ...2000 Textron Inc All Rights Reserved...

Page 24: ...GB 22 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL GB...

Page 27: ...F 25 RANSOMES G PLEX II S rie WD NOMENCLATURE ET MAINTENANCE F...

Page 49: ...F 47 RANSOMES G PLEX II S rie WD NOMENCLATURE ET MAINTENANCE F...

Page 51: ...NL 49 RANSOMES G PLEX II Serie WD ONDERHOUDSHANDLEIDING EN ONDERDELENLIJST NL...

Page 71: ...NL 69 RANSOMES G PLEX II Serie WD ONDERHOUDSHANDLEIDING EN ONDERDELENLIJST NL...

Page 73: ......

Page 75: ...D 73 RANSOMES G PLEX II Serie WD WARTUNGS UND ERSATZTEILHANDBUCH D...

Page 95: ...D 93 RANSOMES G PLEX II Serie WD WARTUNGS UND ERSATZTEILHANDBUCH D...

Page 97: ...D 95 RANSOMES G PLEX II Serie WD WARTUNGS UND ERSATZTEILHANDBUCH D...

Page 99: ...I 97 RANSOMES G PLEX II Serie WD MANUALE DELLA MANUTENZIONE E DELLE PARTI DI RICAMBIO I...

Page 119: ...I 117 RANSOMES G PLEX II Serie WD MANUALE DELLA MANUTENZIONE E DELLE PARTI DI RICAMBIO I...

Page 132: ...Parts 12 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 5b HYDRAULIC TANK FITTINGS...

Page 168: ...Parts 48 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 20 DECALS...

Page 184: ...Parts 64 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 25 REEL ASSEMBLY 1...

Page 186: ...Parts 66 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 26 REEL ASSEMBLY 2...

Page 188: ...Parts 68 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 27 REAR ROLLER...

Page 190: ...Parts 70 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 28 REAR ROLLER...

Page 214: ......

Page 215: ......