GB-10

RANSOMES G PLEX II Series :WD

MAINTENANCE AND PARTS MANUAL

GB

WARNING

•

This procedure MUST be performed as

specified and only by properly trained

service personnel.

Adjusting the speed control screw out (increasing

length) will reduce the mow speed. Adjusting the

speed control screw in (shortening length) will

increase mow speed.

Determine which direction to adjust the mow speed

screw. Loosen the locking nut and adjust speed

control screw, snug up the locking nut and run the

time test again, repeat as necessary. When correct

mow speed has been obtained, tighten the locking

nut (See Fig. 19).

2

1

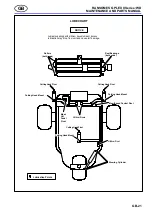

Figure 19

1. Mow Speed Adjustment Screw

2. Locking Nut

TO SET BELLCRANK STOP SCREW:

NOTICE

•

The bellcrank stop screw has been set at

the factory and should

NOT

require

adjustment. If stop screw is loosened or

removed, it

MUST

be properly installed

and adjusted prior to unit operation.

1

2

Figure 20

1. Bellcrank Stop Screw

2. Center Foot Panel

Remove the screws securing the center foot panel

and remove panel (this will allow access to the

lockout link angle).

Loosen the nut on the bellcrank stop screw just

enough to allow the screw to be slid to the left of the

slot (See Fig. 21). Rotate bellcrank clockwise (as

viewed from above) and hold the bushing on the

lockout link angle to the left end of the lockout link

slot (See Fig. 22).

2

1

AS VIEWED

FROM BELOW

BELLCRANK

STOP SCREW

3

Figure 21

1. Bellcrank

2. Lockout Link Angle

3. Lockout Link slot

POSITIONED

TO THE

LEFT OF SLOT

LOCK

OUT LINK

Figure 22

Position Bushing to Left of Slot

Slide the bellcrank stop screw to the left of the slot

located in the foot panel (See Fig. 20) making sure

the bellcrank contacts the stop screw. With the

screw held tightly against the bellcrank, tighten the

stop screw nut.

Install the center foot panel.

CUTTING HEAD LIFT AND LOWER TIMING

Summary of Contents for D722B

Page 2: ...2000 Textron Inc All Rights Reserved...

Page 24: ...GB 22 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL GB...

Page 27: ...F 25 RANSOMES G PLEX II S rie WD NOMENCLATURE ET MAINTENANCE F...

Page 49: ...F 47 RANSOMES G PLEX II S rie WD NOMENCLATURE ET MAINTENANCE F...

Page 51: ...NL 49 RANSOMES G PLEX II Serie WD ONDERHOUDSHANDLEIDING EN ONDERDELENLIJST NL...

Page 71: ...NL 69 RANSOMES G PLEX II Serie WD ONDERHOUDSHANDLEIDING EN ONDERDELENLIJST NL...

Page 73: ......

Page 75: ...D 73 RANSOMES G PLEX II Serie WD WARTUNGS UND ERSATZTEILHANDBUCH D...

Page 95: ...D 93 RANSOMES G PLEX II Serie WD WARTUNGS UND ERSATZTEILHANDBUCH D...

Page 97: ...D 95 RANSOMES G PLEX II Serie WD WARTUNGS UND ERSATZTEILHANDBUCH D...

Page 99: ...I 97 RANSOMES G PLEX II Serie WD MANUALE DELLA MANUTENZIONE E DELLE PARTI DI RICAMBIO I...

Page 119: ...I 117 RANSOMES G PLEX II Serie WD MANUALE DELLA MANUTENZIONE E DELLE PARTI DI RICAMBIO I...

Page 132: ...Parts 12 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 5b HYDRAULIC TANK FITTINGS...

Page 168: ...Parts 48 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 20 DECALS...

Page 184: ...Parts 64 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 25 REEL ASSEMBLY 1...

Page 186: ...Parts 66 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 26 REEL ASSEMBLY 2...

Page 188: ...Parts 68 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 27 REAR ROLLER...

Page 190: ...Parts 70 RANSOMES G PLEX II Series WD MAINTENANCE AND PARTS MANUAL 28 REAR ROLLER...

Page 214: ......

Page 215: ......