OPERATION

1186 MM267 (6–94)

2Ć12

POST OPERATION CHECKLIST – ENGINE

STOPPED

Check skirts for damage, wear, and adjustment.

Check for wire or string tangled on brushes.

Check to make sure LPG tank service valve is

closed.

Check for LPG odor or frost on LPG hoses and

components, indicating a leak.

Check for leaks.

NORMAL SCRUBBING OPERATION

A normal scrubbing operation consists of seven

typical operations: pre-start checklist, starting

machine, scrubbing, draining recovery tank and

emptying debris tray, post operation checklist –

engine operating, stopping machine, and post

operation checklist – engine stopped.

PRE-START CHECKLIST lists things to check

before starting the machine.

TO START MACHINE lists the steps required to

start the machine.

TO SCRUB lists things to keep in mind before and

during the scrubbing operation.

TO DRAIN SOLUTION TANK AND EMPTY

DEBRIS HOPPER lists the steps required to

empty the debris tray and the recovery tank.

POST OPERATION CHECKLIST – ENGINE

OPERATING lists things to check before stopping

the machine engine.

TO STOP MACHINE lists the steps required to

stop the machine.

POST OPERATION CHECKLIST – ENGINE

STOPPED lists things to check after stopping the

machine engine.

PRE-START CHECKLIST

Check under machine for leak spots.

Check engine lubricating oil level.

Check fuel level.

Check for LPG odor or frosting on hoses or

components indicating LPG fuel leak.

Check brakes and controls for proper operation.

Check service records to determine service

requirements.

TO START MACHINE

NOTE: Before starting machine, perform the

pre-start checks.

1. LPG powered machines: Slowly open the

liquid service valve.

NOTE: Opening the service valve too quickly may

cause the service valve check valve to stop the

flow of LPG fuel. If the check valve stops the flow

of fuel, close the valve, wait a few seconds, and

slowly open the valve once again.

2. Gasoline powered machines: When the

engine is cold, pull the choke knob out. Push

choke in after the engine has started and is

running smoothly.

LPG powered machines: When the engine is

cold and exposed to cold temperatures,

press the primer button on the LPG

vaporizer through the hole in the left engine

compartment cover.

3. Turn the on-off switch key to the right.

4. Push the start switch until the engine starts.

Do not operate the starter for more than 10

seconds at a time or after the engine has

started.

NOTE: Do not operate the starter motor for more

than 10 seconds at a time or after the engine has

started. Allow the starter to cool between starting

attempts. The starter motor may be damaged if it

is operated incorrectly.

5. Release the machine parking brake.

6. Drive the machine to the area to be

scrubbed.

Summary of Contents for 1186

Page 1: ...1186 MM267 Rev 05 12 95 Operator Manual ...

Page 8: ...GENERAL INFORMATION 1186 MM267 6 94 vi ...

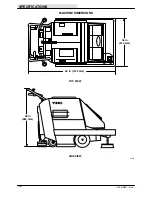

Page 10: ...SPECIFICATIONS 1186 MM267 6 94 1Ć2 ...

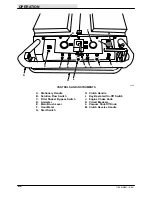

Page 14: ...OPERATION 1186 MM267 6 94 2Ć2 ...

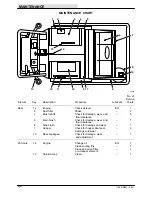

Page 32: ...MAINTENANCE 1186 MM267 6 94 3Ć2 ...

Page 46: ...MAINTENANCE 1186 MM267 6 94 3Ć16 ELECTRICAL SCHEMATIC 06779 ...

Page 68: ...APPENDIX 1186 MM267 6 94 4Ć2 ...

Page 70: ...APPENDIX 1186 MM267 6 94 4Ć4 ...