MAINTENANCE

3Ć9

1186 MM267 (6–94)

7. Squeeze it dry in a cloth.

8. Remove the dry cartridge-type filter nut and

cup.

9. Gently remove the dry cartridge-type air

filter.

10. Clean or discard the dry cartridge-type air

filter.

11. Clean the interior of the air cleaner housing

with a damp cloth. Clean the element

sealing surfaces.

12. Position the cleaned or new, dry

cartridge-type air filter on the engine.

13. Slide the air filter cup over the air filter stud.

14. Thread and tighten the nut on the air filter

stud.

15. Oil the foam pre-cleaner with 1 oz (30 cc) of

clean engine oil. Squeeze the pre-cleaner to

distribute the oil evenly throughout the foam.

16. Slide the foam pre-cleaner over the dry

cartridge-type filter.

17. Position the air filter cover over the air filter

assembly. Tighten the wing nut on the air

filter stud.

FUEL SYSTEM – GASOLINE

FUEL FILTER

The fuel filter traps fuel impurities. It is located

below the air filter. Replace the filter when

diminished fuel flow indicates a dirty filter.

CARBURETOR

The carburetor needs no regular maintenance. It

is set so there is no idle speed––only the normal

operating speed. The initial setting of the idle and

main fuel needle valves is made by turning them

all the way in. Turn the idle fuel adjusting needle

counterclockwise to a minimum of one and

one-quarter turns to a maximum of one and

one-half turns. Turn the main fuel adjusting needle

out counterclockwise to a minimum of one and

three-quarters turns to a maximum of two turns

open. Final adjustment is made with the engine

running and warm.

The carburetor should be adjusted with the fuel

tank approximately one-half full and with the

engine running at approximately 800 RPM. Turn

the main fuel adjusting needle valve out until the

engine begins to lose speed (rich). Note the

position of the needle. Then turn the needle in.

The engine speed may increase, then it will

decrease as the needle is turned in (lean). Note

the position of the needle. Set the needle half way

between the rich and lean positions.

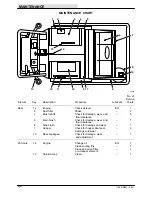

A

B

03075

CARBURETOR ADJUSTMENTS

A. Idle Needle Valve

B. Main Fuel Needle Valve

FUEL SYSTEM – LPG

LPG FUEL SYSTEM

The vapor withdrawal LPG fuel system is made

up of four components which are: the LPG fuel

tank, fuel filter lock, the regulator, and the

carburetor.

LPG fuel flows from the LPG tank, under its own

pressure, to the fuel filter lock. The fuel filter lock

filters unwanted tank scale and deposits out of the

LPG fuel. The fuel filter lock also stops the flow of

LPG fuel when the engine is not operating. The

LPG module controls the fuel filter lock. When the

charging system produces sufficient energy, it

permits an electrical current to open the fuel filter

lock which allows LPG fuel to flow on to the

regulator.

The regulator reduces the pressure of the LPG

fuel to the level required by the carburetor. From

the regulator, the LPG fuel is sent to the

carburetor where it is finally metered into the

combustion chamber air flow.

Summary of Contents for 1186

Page 1: ...1186 MM267 Rev 05 12 95 Operator Manual ...

Page 8: ...GENERAL INFORMATION 1186 MM267 6 94 vi ...

Page 10: ...SPECIFICATIONS 1186 MM267 6 94 1Ć2 ...

Page 14: ...OPERATION 1186 MM267 6 94 2Ć2 ...

Page 32: ...MAINTENANCE 1186 MM267 6 94 3Ć2 ...

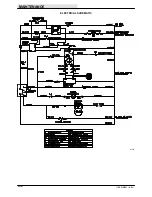

Page 46: ...MAINTENANCE 1186 MM267 6 94 3Ć16 ELECTRICAL SCHEMATIC 06779 ...

Page 68: ...APPENDIX 1186 MM267 6 94 4Ć2 ...

Page 70: ...APPENDIX 1186 MM267 6 94 4Ć4 ...