MAINTENANCE

3Ć5

1186 MM267 (6–94)

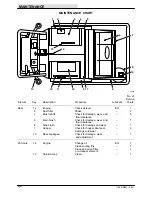

No. of

Service

Interval

Key

Description

Procedure

Lubricant

Points

50 Hours

15

Vacuum fan belt

Check tension and wear

–

1

10

Propelling belts

Check tension and wear

–

2

10

Main brush belts

Check for wear

–

2

9

Side brush belt

Check tension and wear

–

2

2

Battery

Check electrolyte level

DW

1

8

Side brush

Check floor pattern

–

1

3

Main brush

Check floor pattern

–

1

Rotate end-for-end

–

1

4

Brush arm pivot

Lubricate

SPL

2

14

Rear caster

Lubricate

SPL

2

13

Rear squeegee

Lubricate pivot

SPL

1

7

Hopper

Check floor clearance

–

1

100 Hours

12

Engine

Clean or replace and

–

1

gap spark plug

Clean or replace filter element

–

1

5

Drive chains

Check and adjust tension

–

2

Lubricate

SO

2

7

Hopper

Clean inside

–

1

Check floor clearance

–

1

11

Self adjusting sheave

Lubricate

EO

1

6

Dust filter

Clean or replace

–

1

17

Differential

Lubricate

SPL

1

400 Hours

12

Engine

Check valve clearance

–

1

Check breather reed valve

–

1

and gaskets

Clean cylinder head carbon

–

1

deposits

Check starter motor brushes

–

1

16

Side brush gear box

Check lubricant level

GL

1

EO – Engine oil

DW – Distilled water

SPL – Special lubricant, Lubriplate EMB grease, TENNANT Part No. 01433–1

SO – Spray lubricant

GL – SAE 90 weight gear lubricant

NOTE: More frequent intervals may be required in extremely dusty conditions.

Summary of Contents for 1186

Page 1: ...1186 MM267 Rev 05 12 95 Operator Manual ...

Page 8: ...GENERAL INFORMATION 1186 MM267 6 94 vi ...

Page 10: ...SPECIFICATIONS 1186 MM267 6 94 1Ć2 ...

Page 14: ...OPERATION 1186 MM267 6 94 2Ć2 ...

Page 32: ...MAINTENANCE 1186 MM267 6 94 3Ć2 ...

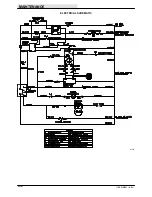

Page 46: ...MAINTENANCE 1186 MM267 6 94 3Ć16 ELECTRICAL SCHEMATIC 06779 ...

Page 68: ...APPENDIX 1186 MM267 6 94 4Ć2 ...

Page 70: ...APPENDIX 1186 MM267 6 94 4Ć4 ...