MAINTENANCE

3Ć29

1186 MM267 (6–94)

TO ADJUST DUST FILTER TO HOPPER

SEALING

1. Park the machine on a smooth, level surface

and set the machine parking brake.

2. Stop the engine.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine.

3. Lift the filter assembly.

4. Make sure stop bolt is making contact with

the filter assembly. If it is, continue with step

5. If it is not, press the round vacuum fan

seal bracket back to allow the assembly to

contact the stop bolt.

B

A

C

03541

STOP BOLT

A. Stop Bolt

B. Hopper

C. Vacuum Fan Seal Bracket

5. Turn the filter stop bolt to the right one-half

turn.

6. Close the filter assembly and check the

clearance between the filter cover and the

hopper. This can be done by placing a 1 in

(25 mm) wide strip of paper between the

filter cover and the hopper. When correctly

adjusted, the paper will be difficult to pull

out. The seal pressure should not be so

great that the hopper will not float. Push the

hopper down to check – it should be able to

go down and return to its original position.

DUST FILTER

The dust filter filters the air which is drawn up

from the main brush compartment by the vacuum

fan. It is located inside the dust filter

compartment. Shake the excess dust from the

filter daily and before emptying hopper. Inspect

and clean or replace the dust filter after every 100

hours of operation.

To clean the dust filter use one of the following

methods:

TAPPING – Tap the filter gently on a flat

surface with the dirty side down. Do not

damage the edges of the filter element or

the filter will not seat properly in the filter

frame.

AIR – Blow compressed air, 35 psi (240

kPa) maximum, through the dust filter

opposite the direction of the arrows. This

may be done with the filter in the machine.

Always wear eye protection when using

compressed air.

WATER – Soak the dust filter in a water and

mild detergent solution. Rinse the dust filter

until it is clean. The maximum water

pressure allowable is 40 psi (275 kPa). Air

dry the wet dust filter; do not use

compressed air.

NOTE: Be sure the dust filter is dry before

reinstalling it in the machine.

Machines equipped with the fine particle filter

option should vacuum the extra filter clean

whenever the standard filter is serviced.

Summary of Contents for 1186

Page 1: ...1186 MM267 Rev 05 12 95 Operator Manual ...

Page 8: ...GENERAL INFORMATION 1186 MM267 6 94 vi ...

Page 10: ...SPECIFICATIONS 1186 MM267 6 94 1Ć2 ...

Page 14: ...OPERATION 1186 MM267 6 94 2Ć2 ...

Page 32: ...MAINTENANCE 1186 MM267 6 94 3Ć2 ...

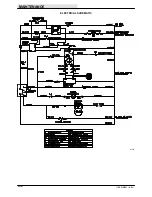

Page 46: ...MAINTENANCE 1186 MM267 6 94 3Ć16 ELECTRICAL SCHEMATIC 06779 ...

Page 68: ...APPENDIX 1186 MM267 6 94 4Ć2 ...

Page 70: ...APPENDIX 1186 MM267 6 94 4Ć4 ...