MAINTENANCE

1186 MM267 (6–94)

3Ć14

CYLINDER HEAD

The cylinder head may develop carbon deposits.

After every 400 hours of operation, remove the

cylinder head and clean it of any accumulated

deposits. Replace the cylinder head, making sure

the cylinder head screws are lubricated with

graphite grease and are returned to the same

hole. Alternately snug the screws; tighten them to

one-half of the specified value, then torque the

screws to 15 to 20 ft lb (20 to 25 Nm).

03076

CYLINDER HEAD SCREW TIGHTENING

SEQUENCE

VALVE TAPPET CLEARANCE

The valve tappet clearance must be inspected

after every 400 hours of operation. The intake

valve clearance should be 0.006 to 0.008 in

(0.15 to 0.20 mm) cold. The exhaust valve

clearance should be 0.017 to 0.019 in

(0.43 to 0.48 mm) cold. Grind off the end of the

valve stem to obtain the proper clearance.

PCV SYSTEM

The pcv system including the reed valve and

gaskets must be inspected after every 400 hours

of operation.

TUNE-UP CHART

Maximum governed speed

2000 rpm

Spark plug gap

0.023 to 0.028 in

(0.58 to 0.71 mm)

gasoline

0.016 to 0.020 in

(0.41 to 0.51 mm)

LPG

Valve clearances, cold

0.006 to 0.008 in

(0.15 to 0.20 mm)

intake

0.017 to 0.019 in

(0.43 to 0.48 mm)

exhaust

Summary of Contents for 1186

Page 1: ...1186 MM267 Rev 05 12 95 Operator Manual ...

Page 8: ...GENERAL INFORMATION 1186 MM267 6 94 vi ...

Page 10: ...SPECIFICATIONS 1186 MM267 6 94 1Ć2 ...

Page 14: ...OPERATION 1186 MM267 6 94 2Ć2 ...

Page 32: ...MAINTENANCE 1186 MM267 6 94 3Ć2 ...

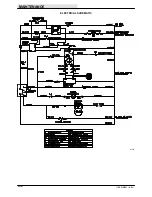

Page 46: ...MAINTENANCE 1186 MM267 6 94 3Ć16 ELECTRICAL SCHEMATIC 06779 ...

Page 68: ...APPENDIX 1186 MM267 6 94 4Ć2 ...

Page 70: ...APPENDIX 1186 MM267 6 94 4Ć4 ...