OPERATION

2Ć11

1186 MM267 (6–94)

TO SWEEP

Plan the sweeping in advance. Try to arrange long

runs with minimum stopping and starting. Sweep

debris from very narrow aisles into main aisles

ahead of time. Do an entire floor or section at one

time.

Pick up oversize debris before sweeping. Flatten

or remove bulky cartons from aisles before

sweeping. Pick up pieces of wire, twine, string,

etc., which could become entangled in brush or

brush plugs. Overlap brush paths.

Sweep as straight a path as possible. Avoid

bumping into posts or scraping the sides of the

sweeper.

1. Move the main brush lever into the (Main

Brush Down) or (Main Brush Free-Float)

position.

2. Move the side brush arm into the down

position.

3. Make sure the solution switch is turned off.

4. Push in the vacuum shut-off knob.

5. Raise the rear squeegee with the squeegee

lever.

6. Sweep as required.

TO DUMP HOPPER

1. Pull the main brush lever into the (Main

Brush Up) position.

2. Pull the side brush arm into the raised

position.

NOTE: The filter shaker by-pass switch must be

in the “on” position to shake the dust filter when

the engine is turned off.

3. Slowly drive the machine up to the dump

site or dumpster. Park on a level surface.

4. Stop the engine and set the machine

parking brake.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine.

5. Lift the filter cover.

6. Lift the front of the debris hopper and pivot

the hopper on the hangers to dump the

debris.

WARNING: Heavy Hopper. Get Help To

Handle.

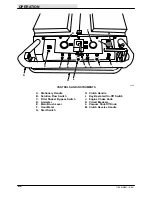

A

06316

DUMPING HOPPER

A. Hopper

7. Lower the hopper.

8. Slowly back the machine away from the

dump site or dumpster.

POST OPERATION CHECKLIST – ENGINE

OPERATING

Check brush pattern for width and evenness.

TO STOP MACHINE

1. Raise the main brush and side brush.

2. Turn the on-off switch key to the left.

Remove the key from the on-off switch.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine And Remove

Key.

3. LPG powered machines: Close the LPG

tank liquid service valve.

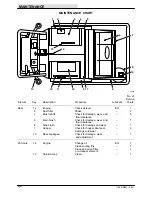

Summary of Contents for 1186

Page 1: ...1186 MM267 Rev 05 12 95 Operator Manual ...

Page 8: ...GENERAL INFORMATION 1186 MM267 6 94 vi ...

Page 10: ...SPECIFICATIONS 1186 MM267 6 94 1Ć2 ...

Page 14: ...OPERATION 1186 MM267 6 94 2Ć2 ...

Page 32: ...MAINTENANCE 1186 MM267 6 94 3Ć2 ...

Page 46: ...MAINTENANCE 1186 MM267 6 94 3Ć16 ELECTRICAL SCHEMATIC 06779 ...

Page 68: ...APPENDIX 1186 MM267 6 94 4Ć2 ...

Page 70: ...APPENDIX 1186 MM267 6 94 4Ć4 ...