START-UP

•

Check if there are any gaps between the process tube and the tube adapters and

between the radiation shield and the quartz tube. If there are gaps, fill them up with

heat resisted insulating material, such as quartz wool.

•

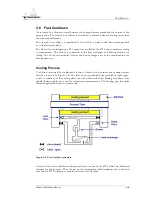

Push the thermocouple back, till it touches the quartz tube (seeFigure 4-3). When the

thermocouple is placed correctly, the pressure spring can be placed on the

thermocouple. Check if the pressure spring is in its right position (see Figure 4-3). If

not, then adjust it. The furnace is now ready to be heated up carefully.

4.6 Test and Calibration Procedure

See Technical Manual DTC, chapter 4.0

4.7 Pre-Cleaning of the Process Tube

Process Tubes supplied by Amtech/Tempress have been pre-cleaned by our supplier, but it

is recommended that a further clean is carried out before installing.

1. In case of Quartz process tubes:

They may be cleaned by using a solution of 1: 10 HF/Dl-water, for 2-3 minutes. After

etching, the tube should be rinsed in DI-water sufficiently to remove all traces of the acid and

dried with dry nitrogen.

2. In case of Sic process tubes (Crystal) and Paddles:

Some process tubes and liners may have a Zircon coating on the OD. It is not

recommended to wet clean these products with Hydrofluoric (HF) acid. This will cause the

coating to peel and flake off.

To prevent the potential of accidental breakage, the components should not be subjected to

high temperatures immediately after wet cleaning. Components should be allowed to dry at

room temperature for 12 hours or longer. After room temperature drying, it is preferred to

insert components at 300

0

- 400

0

C for 1-2 hours, and then use normal 300

0

C/hr ramp-up

cycle.

Initial Room Temperature Clean:

•

Use normal quartz cleaning procedure including HF and/or NH

2

OH solutions.

Dilute HF solutions have an equal amount of HCL, eg.: HF:HCL:H

2

O=1:1:4.

•

Do not use concentrate HF and HNO

3

combined.

•

Rinse in DI water and dry air.

Initial High Temperature Clean:

•

Heat to 50

0

C higher than intended process temperature or higher if practical

(cleaning/time:1100

0

C/48hr, 1200

0

C/16hr, 1300

0

C/8hr).

•

P-tubes: Heat up to desired cleaning temperature in 300

0

C steps with 10 minute hold

at each step of stabilization.

F

URNACE

R

EFERENCE

M

ANUAL

4-6