DESCRIPTION

2.6 Fast

Cooldown

Air is forced by a blower to travel between the heating element mantle and the outside of the

process tube. The direction of airflow is alternated to achieve balanced cooling faster than

the conventional furnace.

The air used for cooling is re-circulated. It is cooled by a water-cooled heat exchanger built

in, in the furnace cabinet.

The blower is a centrifugal type. The speed is controlled by the DTC and is varied according

to requirements. The blower is connected to the heat exchanger and heating element via

tubing. The Cool down modules (blower and heat exchanger) are both situated behind the

heating elements.

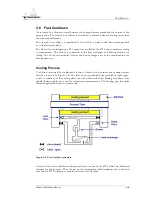

Cooling Process

Cool down is assisted by conditioned air that is forced to flow between the heating element

and the process tube (Figure 2-4). The flow of air is periodically reversed left-to-right; right-

to-left to equalize out the cooling effect over the whole wafer load. During cool-down, only

paddle thermocouples are used for temperature measurement. The flowing past the spike

thermocouples makes their use inaccurate.

Figure 2-4 Fast Cooldown principle

Control of the valves and blower during cool-down is done by the DTC which has dedicated

software for the purpose. The cool rate in the temperature table determines the cool down

time and the DTC attempts to maintain this rate over all zones.

F

URNACE

R

EFERENCE

M

ANUAL

2-6