Energy 2510 B

Vers. 002

GB

22

7.4 Maintenance operations to be carried out

by qualified personnel

To carry out certain servicing operations, it is

possible to extract the engine-alternator assem-

bly from the front. (See paragraph 4.3.).

This will make it easier to obtain access to all the

inside parts of the generating set for unscheduled

maintenance or repair operations.

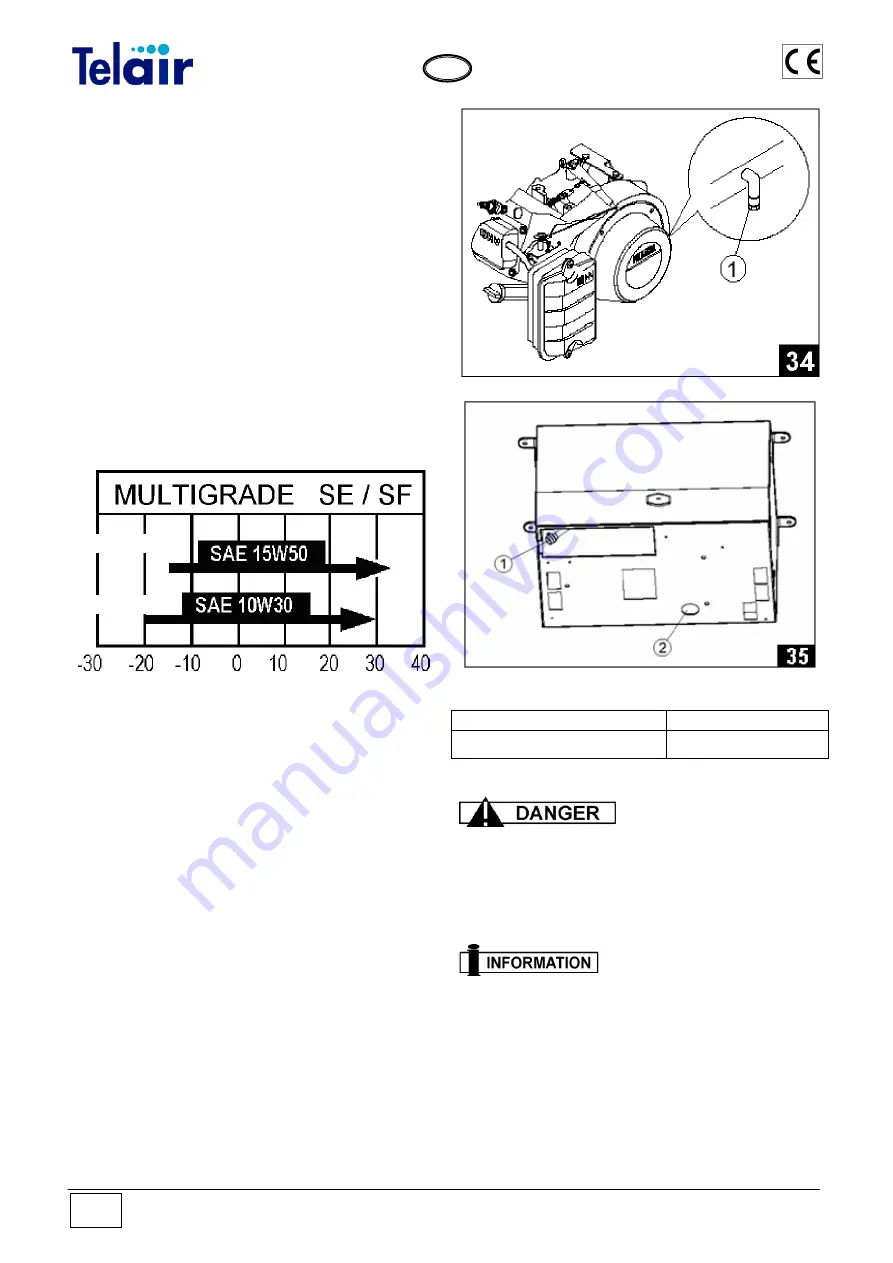

7.4.1 Engine oil replacement

Use multigrade oil for four-stroke petrol engines

having a SAE viscosity degree suited to the cli-

mate the generating set is working in (see table

and detailed instructions in the engine use and

maintenance manual).

To make it easier to drain the spent engine oil, it

is advisable to let the engine run for 3 - 5 min-

utes; in this way, the oil will be more fluid and

emptying will be quicker and more thorough.

Undo the special cap on the soil sump (Fig.34

Ref.1) which can be reached through a special

hole under the sound-proofing case (Fig.35 Ref.

2) and allow all the contained oil to be drained to

a collecting tank.

After doing this, screw the cap back on and re-

store the oil level inside the oil sump, using the

filler hole (Fig.33 Ref. 2).

Check the following table for the right amount of

oil to pour in the sump (Table 2).

Table 2

MODEL

Oil quantity (litres)

Energy 2510 B

0.6

•

Hot oil can scald.

•

Causing the engine to run when the oil

level is too low can seriously damage it.

•

Check the oil level when the engine has

been turned off.

Spent oil should not be

disposed freely in the environment but taken

to special disposal centres carrying out dis-

posal and/or recycling in compliance with the

applicable law provisions in force in the

country of use.

For cold climates

For hot climates