85

WARNING!

Never use a compressor to evacuate a system. Instead, use a high vacu-

um pump specifically designed for that purpose.

Never start the compressor while it is under deep vacuum. Always break a vacuum with

refrigerant charge before energizing the compressor.

Failure to follow these instructions can damage the hermetic terminal and may result in

terminal venting. As always, to reduce the risk of serious injury or death from fire due

to terminal venting, never energize the compressor unless the protective terminal cover

is securely fastened.

Charge the System and Check the Pressure Drop

Charge the system and place in operation. Follow the safety precautions outlined in “Sys-

tem Charging” on pages 5-6. Immediately after startup, check the pressure drop across

the suction line filter-drier. This will serve two purposes:

»

Verify that the filter-drier selection was properly sized.

»

Serve as a base point to which subsequent pressure checks can be compared.

Because the permissible pressure drop across the drier is relatively small, it is suggested

that a differential pressure gauge be used for the measurement.

Measure the Pressure Drop

After the system has been operating for an hour or so, measure the pressure drop across

the suction line filter-drier.

In the case of Compressor Housing Contamination, little change should be noted. The

pressure drop will, in most instances, be below that tolerable for a permanent installation

(see Table 5-7).

On the other hand, where System Contamination occurred, an increased pressure drop

will be measured. Change the suction filter-drier and the liquid line filter-drier whenever

the pressure drop approaches or exceeds that allowed for temporary operation during

cleanup (see Table 5-8).

Keep changing both the suction and liquid line filter-driers until the pressure drop stabilizes

at a figure equal to or below that permitted for permanent operation in a system (see Table

5-7). At this point, it is the service person’s option as to whether to leave the suction drier

in the system or remove it from operation.

If the system is to be opened to permit the permanent removal of the suction filter-drier, the

liquid line filter-drier should be changed once more.

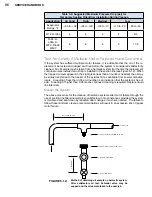

Table 5-7: Suggested Maximum Pressure Drop (psi) for

Permanent Suction Filter-Drier Installation

Application

Air Cond

High

Medium

Low

Evaporator

Range, °F

+55 to +32

+55 to +20

+30 to -10

+10 to -20

-20 to -40

R-12, R-134a

2

2

1 1/2

1/2

1/2

R-22,

R-404A, R-

407C, R-502,

R-507

3

3

2

1

1/2

Summary of Contents for AH5540E

Page 1: ...Hermetic Compressor Service Handbook Wholesale Distribution North America...

Page 2: ......

Page 3: ...Hermetic Compressor Service Handbook Ann Arbor MI 48108 REV 3 11...

Page 4: ......

Page 8: ......

Page 9: ...Chapter 1 General Service Safety Precautions...

Page 16: ......

Page 17: ...Chapter 2 Model and Application...

Page 22: ......

Page 23: ...Chapter 3 Compressor Motor and Component...

Page 36: ......

Page 37: ...Chapter 4 Servicing...

Page 38: ...30 SERVICE HANDBOOK...

Page 79: ...71...

Page 80: ......

Page 81: ...Chapter 5 Installation and Replacement...

Page 96: ......

Page 97: ...Liquid refrigerant migration to compressor FIGURE 6 1 Chapter 6 Operation...

Page 108: ......

Page 109: ...Appendix...

Page 113: ...105 Reciprocating Compressor FIGURE A 2 Internal view of typical air conditioning compressor...

Page 118: ...110 SERVICE HANDBOOK Notes...

Page 119: ......