5

•

Use a pressure regulating valve and pressure gauges.

Commercial cylinders of nitrogen contain pressures in excess of 2000 psig at 70

°

F. At

pressures much lower than 2000 psig, compressors can explode and cause serious

injury or death. To avoid over pressurizing the system, always use a pressure-regulating

valve on the nitrogen cylinder discharge (see Figure 1-7). The pressure regulator must

be able to reduce the pressure down to 1 or 2 psig and maintain this pressure.

The regulating valve must be equipped with two pressure gauges:

»

one gauge to measure cylinder pressure, and

»

one gauge to measure discharge or downstream pressure.

•

Use a pressure relief valve.

In addition to a pressure regulating valve and gauges, always install a pressure relief

valve. This can also be a frangible disc type pressure relief device. This device should

have a discharge port of at least ½” MPT size. The valve or frangible disc device must

be set to release at 175 psig (see Figure 1-7).

•

Do not pressurize the system beyond 150 psig field leak test pressure.

When field testing a system for leaks, 150 psig is adequate test pressure.

• Disconnect nitrogen cylinder and evacuate the system before connecting the refrigerant

container.

Disconnect the nitrogen cylinder and evacuate the system according to the equipment

manufacturer's recommendations prior to charging the system.

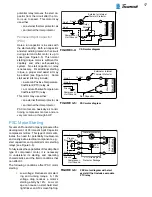

System Charging

Failure to properly charge the system can result in serious injury or death from explosion or fire.

Follow these precautions when charging a system:

•

Do not operate the compressor without charge in the

system.

Operating the compressor without a charge in the

system can damage the hermetic terminal. As always,

to avoid serious injury or death from terminal venting

with ignition, never energize the compressor unless the

protective terminal cover is securely fastened.

•

Use proper refrigerant.

Use only the serial label refrigerant when charging

the system. Using a different refrigerant can lead to

excess system pressure and an explosion. Use of a

refrigerant other than the serial label refrigerant will void the compressor warranty.

•

Do not overcharge a refrigeration or air conditioning system.

Overcharging a refrigeration or air conditioning system can result in explosion. To avoid

serious injury or death, never overcharge the system. Always use proper charging

techniques. Limit charge amounts to those specified on the system equipment serial

label or in the original equipment manufacturer’s service information.

Overcharging the system immerses the compressor motor, piston, connecting rods,

and cylinders in liquid refrigerant. This creates a hydraulic block preventing the

compressor from starting. The hydraulic block is also known as locked rotor.

Continued supply of electricity to the system causes heat to build in the compressor.

This heat will eventually vaporize the refrigerant and rapidly increase system pressure.

If, for any reason, the thermal protector fails to open the electrical circuit, system

pressure can rise to high enough levels to cause a compressor housing explosion.

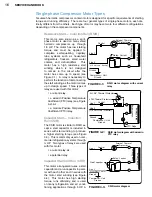

Gauges

To System

Relief Valve

Regulating

Valve

FIGURE 1-7

Dry nitrogen cylinder with

attached pressure gauges

needed for pressure testing

for leaks and purging.

Summary of Contents for AH5540E

Page 1: ...Hermetic Compressor Service Handbook Wholesale Distribution North America...

Page 2: ......

Page 3: ...Hermetic Compressor Service Handbook Ann Arbor MI 48108 REV 3 11...

Page 4: ......

Page 8: ......

Page 9: ...Chapter 1 General Service Safety Precautions...

Page 16: ......

Page 17: ...Chapter 2 Model and Application...

Page 22: ......

Page 23: ...Chapter 3 Compressor Motor and Component...

Page 36: ......

Page 37: ...Chapter 4 Servicing...

Page 38: ...30 SERVICE HANDBOOK...

Page 79: ...71...

Page 80: ......

Page 81: ...Chapter 5 Installation and Replacement...

Page 96: ......

Page 97: ...Liquid refrigerant migration to compressor FIGURE 6 1 Chapter 6 Operation...

Page 108: ......

Page 109: ...Appendix...

Page 113: ...105 Reciprocating Compressor FIGURE A 2 Internal view of typical air conditioning compressor...

Page 118: ...110 SERVICE HANDBOOK Notes...

Page 119: ......