76

SERVICE HANDBOOK

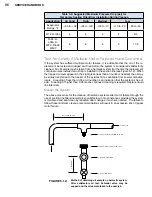

Refrigerant Line Sizes

R-12, R-134a and R-404A Refrigerant Line Sizes for Remote Systems

Commercial Refrigeration

Refer to Tables 5-1 through 5-8. The recommended suction line sizes are based on a pres-

sure drop no greater than the equivalent of a 1.5°F change in saturation temperature. The

resulting pressure drop should provide sufficient refrigerant velocities necessary for proper

oil return for suction lines up to 100 ft in length.

Suction line sizes that provide a minimum 1500 ft/min velocity are provided as a reference

when sizing risers.

On heat pump systems, the lines serving as both a discharge line and suction line should

be sized as a suction line.

Refer to these installation considerations for good oil return on commercial systems.

•

Slope horizontal suction line downwards in the direction of the compressor at least ½”

fall per 10 feet of line.

•

For systems using a thermostatic expansion valve (TEV), the valve should be set to its

proper setting. A typical superheat setting for commercial refrigeration applications is

6°F to 8°F. For low temperature refrigeration, a superheat setting of 4°F to 6°F is usually

appropriate.

•

In the case of a flooded type evaporator (bottom feed, top suction header, large inter-

nal volume, low refrigerant/oil velocities), it is necessary to maintain a liquid spillover

into the suction line so as to return the oil with the liquid refrigerant and to minimize

oil trapping in the evaporator. If because of the spillover, the return gas is “wet” at the

compressor, a suction line accumulator should be installed adjacent to the compres-

sor.

•

Install a suction accumulator to prevent liquid refrigerant from entering the compressor,

particularly when long suction lines are being used.

•

On multiple evaporator systems, prevent oil and refrigerant from collecting in an idle

coil. If the evaporator coils are to operate independently of each other, each should

have its own suction riser sized to the coil’s capacity.

•

Insulate suction lines.

•

Suction lines longer than 100 ft are not recommended.

The recommended discharge line sizes are based on a pressure drop no greater than the

equivalent of a 1.5°F change in saturation temperature. Discharge line sizes that provide a

minimum 1500 ft/min velocity are provided as a reference when sizing risers.

The recommended liquid line sizes are based on a pressure drop no greater than the

equivalent of a 1°F change in saturation temperature. Liquid lines sizes that provide a

minimum 100 ft/min velocity are provided as a reference.

Summary of Contents for AH5540E

Page 1: ...Hermetic Compressor Service Handbook Wholesale Distribution North America...

Page 2: ......

Page 3: ...Hermetic Compressor Service Handbook Ann Arbor MI 48108 REV 3 11...

Page 4: ......

Page 8: ......

Page 9: ...Chapter 1 General Service Safety Precautions...

Page 16: ......

Page 17: ...Chapter 2 Model and Application...

Page 22: ......

Page 23: ...Chapter 3 Compressor Motor and Component...

Page 36: ......

Page 37: ...Chapter 4 Servicing...

Page 38: ...30 SERVICE HANDBOOK...

Page 79: ...71...

Page 80: ......

Page 81: ...Chapter 5 Installation and Replacement...

Page 96: ......

Page 97: ...Liquid refrigerant migration to compressor FIGURE 6 1 Chapter 6 Operation...

Page 108: ......

Page 109: ...Appendix...

Page 113: ...105 Reciprocating Compressor FIGURE A 2 Internal view of typical air conditioning compressor...

Page 118: ...110 SERVICE HANDBOOK Notes...

Page 119: ......