54

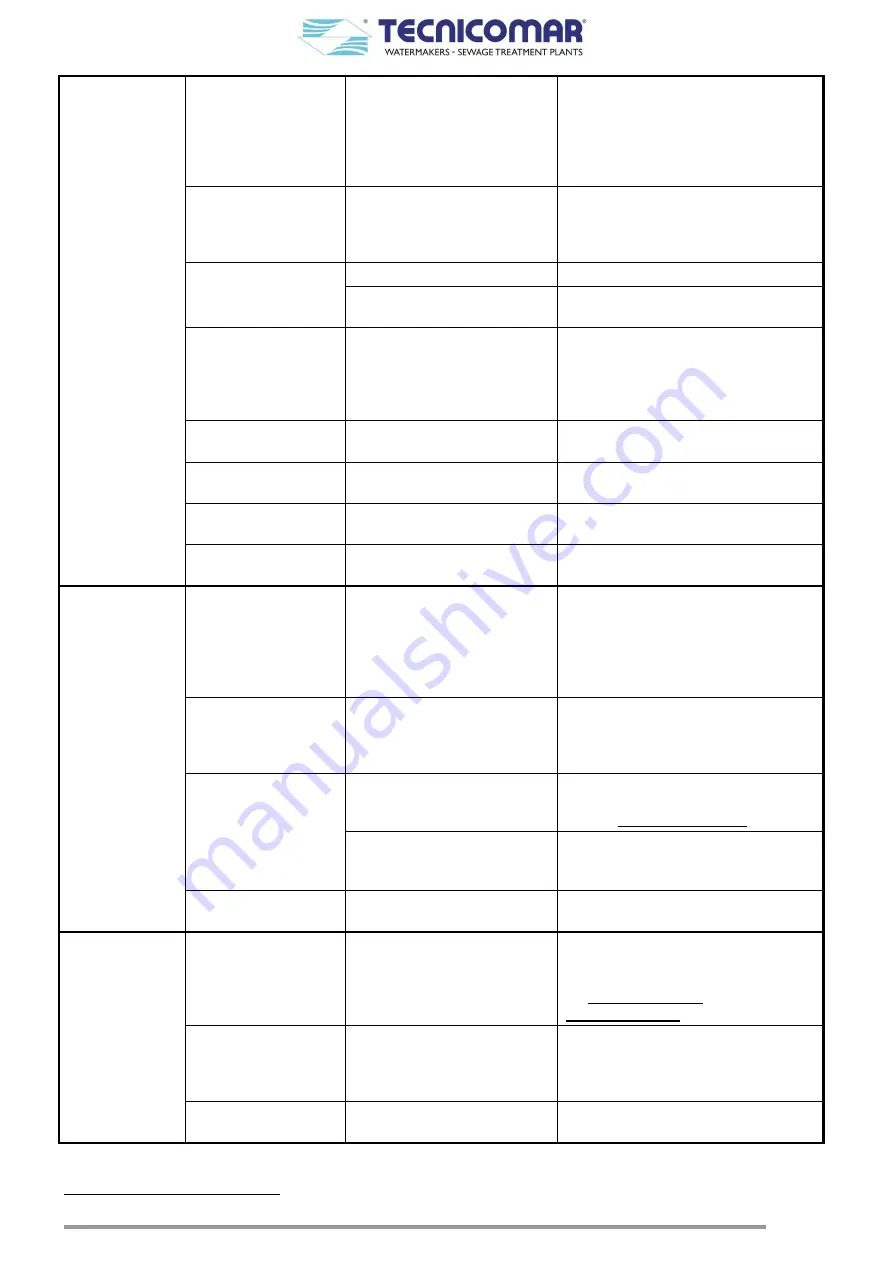

The system shuts

down for

OVERLOAD

ALARM

fault.

(

The display

shows the

OVERLOAD /

HIGH

PRESSURE

ALARM screen

).

Wrong settings of the

black switch button of

the circuit switch

breakers.

Verify that black switch button

of the circuit switch breakers,

installed inside Main Control

Box, is in OFF position, with

the switch button pushed out

from the switch circuit breaker.

Set the black switch button of the circuit

switch breakers, in ON position, with the

switch button pressed inside the switch

circuit breaker; by pushing the black

switch button.

Incorrect settings of the

circuit switch breakers

threshold.

Check the threshold setting

value of the circuit switch

breakers, installed inside the

Main Control Box.

Operate on the circuit switch breakers to

set the threshold to the correct value

shown on the attached Test Report.

Circuit switch breakers

keep tripping.

Short circuit of the system.

Solve the system short circuit.

Circuit switch breakers unusable

or of incorrect rating.

Replace the circuit switch breaker.

Wrong power supply

voltage.

Verify the match between the

voltage of the power supply line

and the ECOmar S STP

admissible voltage.

Power the plant with a voltage suitable to

that indicated on the system nameplate;

or if it is not possible, replace the

ECOmar S STP with one suitable with

the power supply line voltage.

Any filling pump

overload.

Check the absorption of each

supplied filling pump.

Individuate the pump overload cause and

solve it.

Seawater pump

overload.

Check the absorption of the

seawater pump.

Individuate the pump overload cause and

solve it.

Macerating pump

overload.

Check the absorption of the

macerating pump.

Individuate the pump overload cause and

solve it.

Broken control box.

All previous checks have not

been successful.

Repair or replace the main control box.

The system shuts

down for

HIGH

PRESSURE

ALARM

fault

.

(

The display

shows the

OVERLOAD /

HIGH

PRESSURE

ALARM screen

).

Wrong settings of the

black switch button of

the circuit switch

breakers.

Verify that black switch button

of the circuit switch breakers,

installed inside Main Control

Box, is in OFF position, with

the switch button pushed out

from the switch circuit breaker.

Set the black switch button of the circuit

switch breakers, in ON position, with the

switch button pressed inside the switch

circuit breaker; by pushing the black

switch button.

Wrong or inefficient

ventilation of the

treatment tank.

Check the presence of any

obstructions or blockage in the

air relief or along the vent line.

Remove any obstructions from the air

relief and leave it as free as possible.

Remove any obstructions from the vent

line and leave it as free as possible.

Pressure switch

malfunctioning.

Check the correct setting of the

pressure switch threshold.

Calibrate the pressure switch to the value

reported in the attached Test Report

(refer to

Alarms Description

section).

Check if the pressure switch

works correctly giving the

correct free voltage signal.

Repair or replace the pressure switch.

Broken control box.

All previous checks have not

been successful.

Repair or replace the main control box.

The ECOmar S

STP starts up, but

there is no or low

quality

visualization on

the display.

The display need

contrast calibration.

Open the main control box and

check the display contrast

calibration, by acting on the

trimmer P2.

Re-calibrate the display contrast by

acting on the trimmer P2 installed on the

rear side of the P.C.B. PRO14 (refer to

the

MAINTENANCE

INSTRUCTIONS

section).

Incorrect settings of the

display backlight.

Check the set value of the

“

Display Backlight Timer

”

parameter on the parameter

programming page.

Set properly the “

Display Backlight

Timer

” parameter (refer to parameters

programming procedure).

Broken control box.

All previous checks have not

been successful.

Repair or replace the main control box.

*

Only for ECOmar S supplied with Treatment Tank in PP.