17

7.5.3

Protections

It is necessary to consider that even if a system possess all the precautions and protections, it will never represent a zero risk

level.

DANGER:

This paragraph highlights some aspects linked to the risk caused by thermal factors. The system

components that may be more subjected to overheating are the U.V. sterilizer, the filling, sea water and

macerating pumps. These components even if equipped with all the precautions needed to limit the dangers

from contact with hot parts, will never assure the absolute harmlessness since there are parts that could reach

temperature higher than 60°C.

WARNING:

The trained operator when approaching the system must observe all the warning panels.

7.5.4

General Instructions for Safety Use

WARNING:

Before start-up the system or any of its loose parts, it is recommended that the operator memorize

the previous paragraphs and all the following informations:

♦

The manufacturer cannot prevent all possible dangerous situations in the conditions of use, installation and

maintenance of the ECOmar S STP;

♦

The operations and/or procedures for use not recommended and/or indicated in the manual will always be notified to

Tecnicomar for confirmation;

♦

If a not recommended procedure will be used, the user must check for safety of people, things and pet;

♦

It is necessary to consider that even if a system possess all the precautions and protections, it will never represent a

zero risk level. It is forbidden to remove boards and protections of the system, especially during the working;

♦

Same for electrical systems, they can represent a danger also when placed in not operative mode since they have parts

under permanent voltage;

♦

The electrical board and all the electrical systems are realized according to the applicable norms.

WARNING:

For safety, it is necessary to observe the following precautions:

♦

Before operating the maintenance on the system or on any of its loose parts it is necessary to assure that it has been

turned off and no one can, accidentally, change its configuration or turn it on;

♦

When turned on, the system presents moving parts, pay attention to not approach the system with flapping objects,

smocks, jackets, ties, chains, bracelets, etc.;

♦

The system produces noise, the use of the headphones is necessary;

♦

It is forbidden to turn on the system before finishing the installation and carrying out the test with positive result. Even

so, the system can represent source of danger and lethal accidents.

7.6

Before Turning on

7.6.1

Checks before Turning On

Before turning on the system, it is necessary to carry out the following controls:

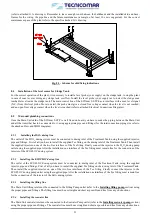

Verify that every mechanical parts, included all the elements and fitting , are well installed;

Verify that instruments and materials are not left around;

Verify that the earthing system connections are correctly done;

Verify the efficiency of the system earthing;

Verify that the lamps of the U.V. sterilizer are correctly fitted into their sockets with the relative protective covers.

In case of three-phase supply, verify the phases correspondence between ECOmar S STP and electrical source;

Verify that the hydraulic circuit ensures a perfect seal.

7.6.2

Useful Advice

•

Familiarize yourself with the sewage treatment plant so that you know all the details and to promptly report any

anomaly that, if neglected, could lead to heavy faults;

•

Maintenance intervention and settings on the plant must be done with system turned off and with no power supply;

•

Disposal of waste from maintenance operation of the system or of any of its subparts (exhausted oil, additives, etc.)

and management of the life cycle, must be done according to the local norms and to the ambient respect. They must

be delivered to the appropriate authorised firms or bodies for the disposal;

•

Spare parts must be original ones;

•

Do not carry out repair operations if not authorised and trained;

•

Check the noise or vibration sources that can be cause of faults or failures;

•

Immediately report leaks of oil, water or other liquid;