-

OPERATORS MANUAL

Page 17

Should the failure or damage come from the SPINJET 6200, use

the table below to identify possible causes and their remedies. If

the outcome is ‘Call service’ or unidentified, the contact is

TechSage or its reseller.

In this case, reset the error message, if any, on the panel by

keeping the power button pressed for more than two seconds.

Turn the SPINJET

off

. Make sure that DUPLEXER has been set to

NO on the Printer. Send jobs using single side, but otherwise

similar to the trouble condition, to the printer and check whether

it passes through the SPINJET and exits from its upper slot. If

this can be done without the occurrence of a problem, the

SPINJET should be left in this position for continued

single

sided

printer use until service can be carried out.

In all other cases, leave the SPINJET Front Unit tilted down and

turned off.

Please note:

Setting DUPLEXER to NO will disable all

communication between the Printer and the SPINJET and double

sided printing is disabled.

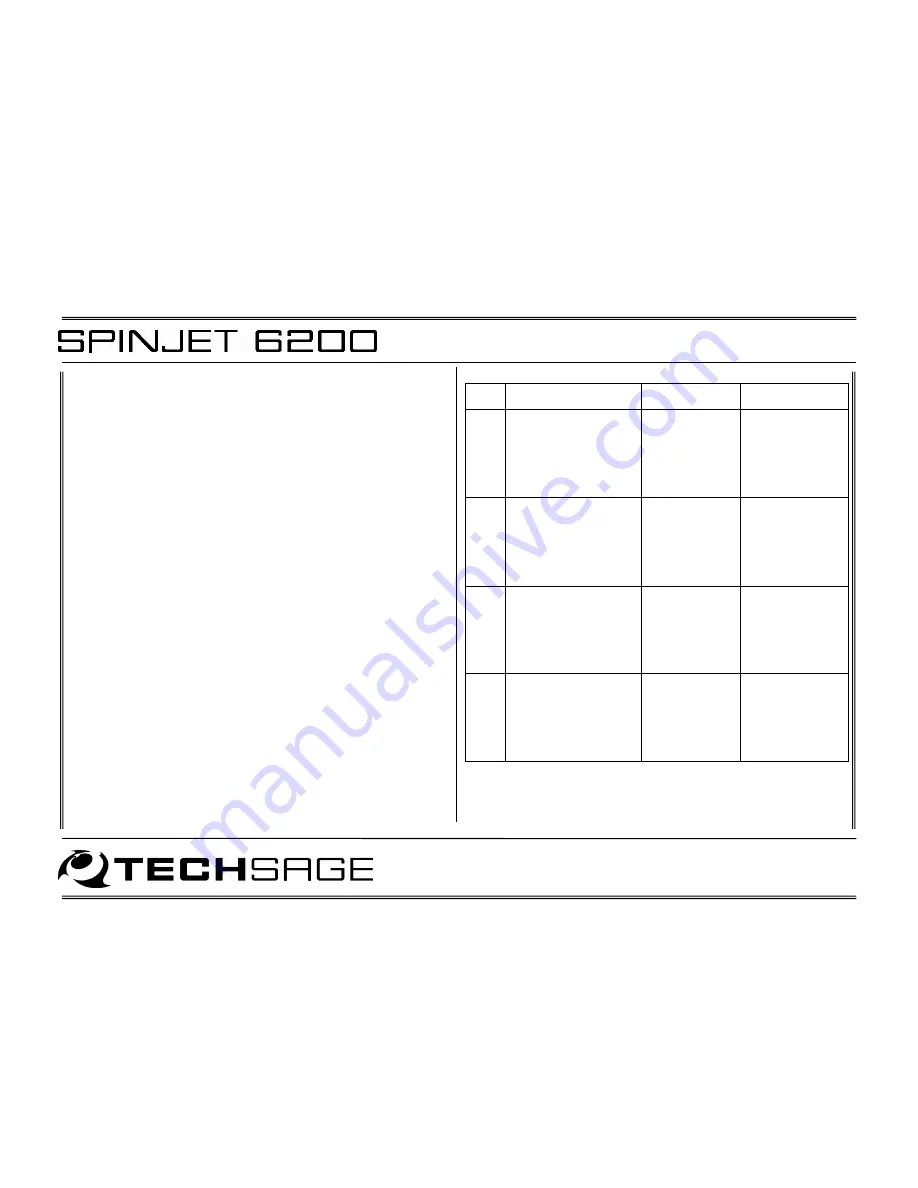

No.

Problem

Most probable

cause

How to solve

problem

1a

Flashing yellow INFO

LED switching on and

Error 01 indi-cated on

Designjet control

panel.

New print job

has been sent

when SPINJET

in lower

position.

Move SPINJET to

upper position

and press Enter

on printer

display.

1b

Flashing yellow INFO

LED switching on and

Error 01 indi-cated on

Designjet control

panel.

Front unit not

butted fully up

against the

Designjet.

Check for proper

contact with

Designjet at

rubber bumper.

2

Flashing yellow INFO

LED switching on and

Error 02 indi-cated on

Designjet control

panel.

SPINJET moved

to lower

position during

print job.

Check printer

and move

SPINJET to upper

position when

Printer enters

‘Ready’ mode.

3

Flashing yellow INFO

LED switching on and

Error 03-06 indicated

on Designjet control

panel.

Inoperative

sensor or

motor.

Call service.