Page 64 sur 72

www.technomark-marking.com

TECHNOMARK

1 Allée du développement

42350 LA TALAUDIÈRE (France)

Tel : +33 (0) 4 77 22 25 91

Fax : + 33 (0) 4 77 22 38 93

E-mail : [email protected]

User Guide GRAPHIX_v1.4_UK

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

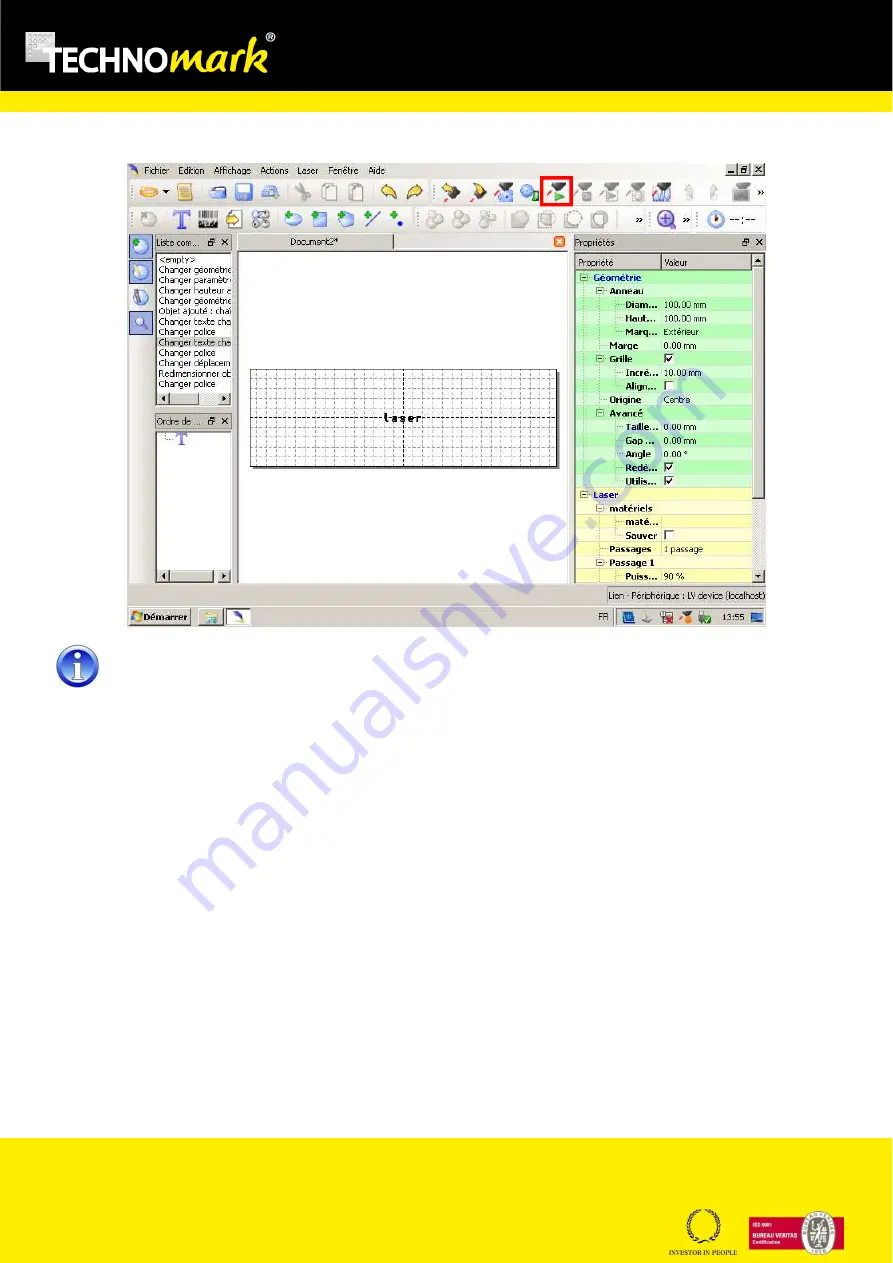

9)

Press the "

Send marking

" button in the "

Laser

" tool bar to start the marking process:

You can stop marking using the "stop" buttons on the "laser" tool bar or on the control desk.