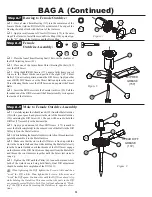

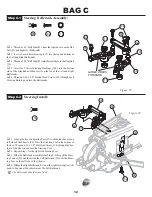

Step A-18

BAG A (Continued)

7

q

1. Locate the smallest of the Allen Wrenches, 0.050 (128), and

place it through the slot in the Outdrive/Diff Half (87) containing the

Diff Screw (91). Slide the Wrench all the way against the Screw. By

handling the Outdrive/Diff Half with the Wrench inserted, the Diff

Screw will be held in place while finishing the assembly of the Differ-

ential.

q

2. Apply a small amount of Clear Diff Grease (172) to the outer

ridge of the Outdrive. Install the remaining Diff Ring (108), again

lining up the "D" shape of the Outdrive/Diff Half with the "D" shape

of the Ring.

IMPORTANT NOTE:

Do not glue the Diff Rings to the

Outdrive/Diff Halves. Doing so may not allow the Rings to mount flat

on the Outdrive.

Diff Drive Ring to Female Outdrive:

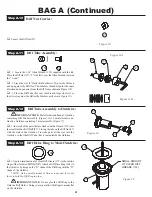

Step A-19

q

1. Carefully replace the Allen Wrench (125) with a pen or pencil

from the Male Outdrive (87). The pen will be used to hold the Diff Nut

(27) assembly in the bottom side.

q

2. Apply a fairly heavy coat of Clear Diff Grease (172) to the

exposed side of the Diff Ring (108) on the Female Outdrive.

q

3. While holding the Female Outdrive with Allen Wrench inserted,

carefully assemble it to the Male Outdrive.

q

4. Make sure that the slot in the Diff Screw is lined up with the

slot in the Female Half and then while holding the Male Half, slowly

turn the Female Outdrive until the threads of the Diff Screw engage

on the threads of the Diff Nut (27). Remove the pencil from the Male

Half and thread the two Outdrives together until the Screw just starts

to snug up.

q

5. Tighten the Diff until the Pulley (42) cannot be turned while

both of the Outdrives are being held firmly. Final Diff adjustment

should be made after completion of the XXX-4 G+.

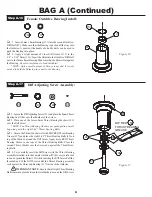

When tightening the Diff, tighten the Screw a little and then

"work" the Diff a little. Then tighten the Screw a little more and

"work" the Diff again. Continue this until the Diff doesn't slip while

holding the Outdrives. This ensures that the parts in the Diff are

properly seated. Refer to Tech Tips for final adjustment. "Working"

the Diff is done by rotating the Outdrives in opposite directions.

Outdrive Assembly:

Figure 18

Figure 19

PENCIL

108

27

87

42

87

CLEAR DIFF

GREASE

91

(172)

128

108

87

91

108

128

SMALL AMOUNT

OF CLEAR DIFF

GREASE (172)