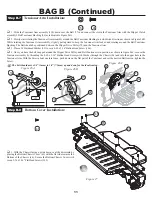

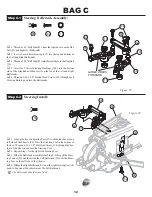

BAG C (Continued)

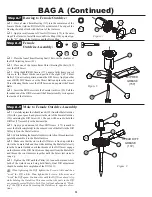

Figure 33

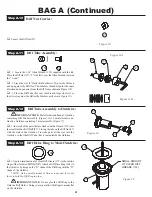

Figure 35

Figure 34B

Figure 34A

15

q

1. Thread a Short Plastic Rod End (10) onto each end of the 4-40

x 5/8" Set Screw (137). Tighten both sides equally until the Rod is the

same length as the one shown in Figure 34B.

q

1. Attach one Rod End (10) to the Ball Stud (80) in the Servo

Saver Arm (39), and the other to the Ball Stud in the Drag Link (32), as

indicated in Figure 35.

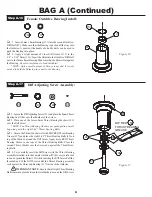

Step C-6

Servo Install:

q

1. Install the servo onto the Chassis (46). The pins from both

Servo Mounting Posts (34), (35) should fit into the holes and sit flat

against the Chassis.

q

2. Secure the servo to the Chassis with two 4-40 x 3/8" Flat Head

Screws (134).

Step C-7

137

10

137

10

Step C-8

Servo Link Install:

134

10

80

32

137

39

81

46

34

134

Servo Link: