409-35001

Rev C

60

of 92

“Connector Drag Enabled/Disabled”

–

Toggle this button

to “Enabled” to allow the user to drag and

drop connectors in the part viewer to set their x and y location on the board. To prevent accidental

modification of connector locations, toggle the button to “Disabled”.

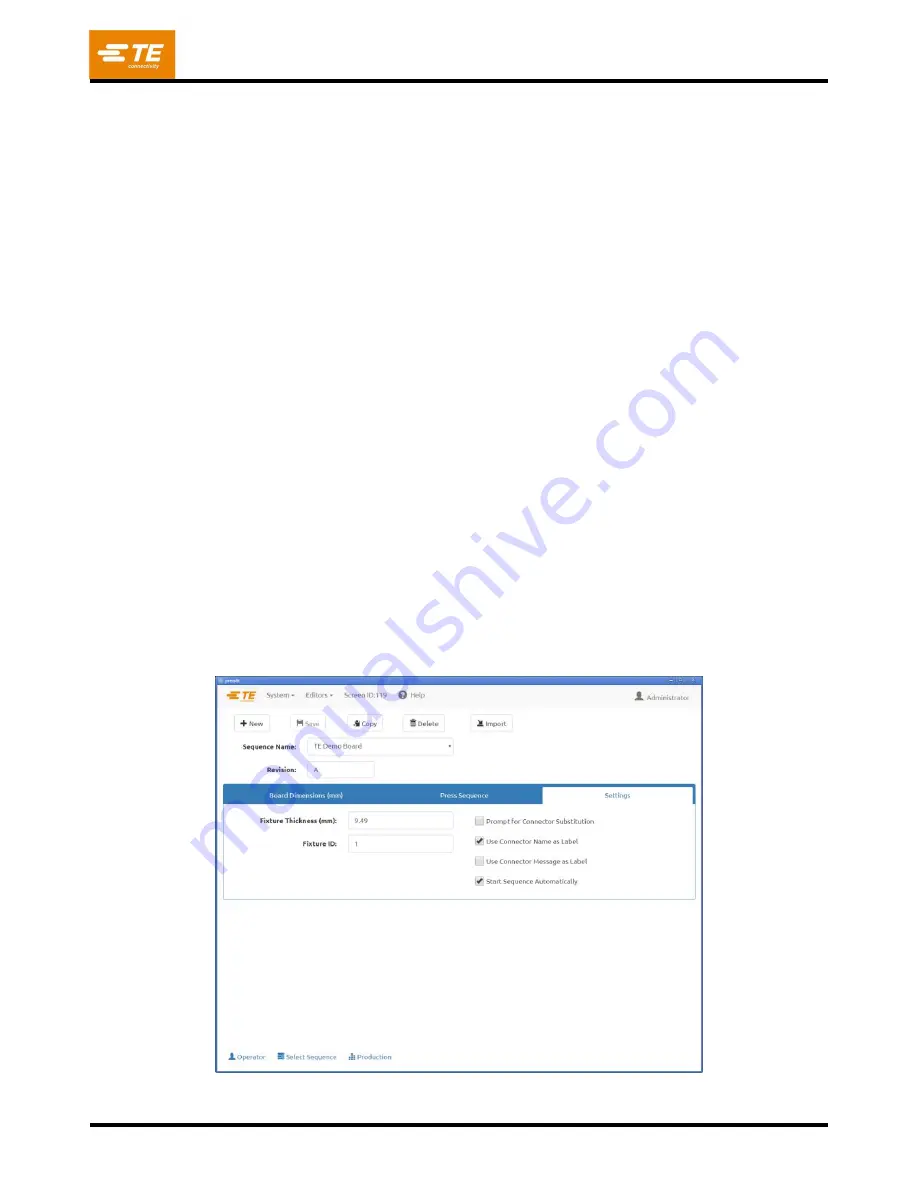

Settings Tab

“Fixture Thickness”

- This is

the thickness of the fixture or “platen” that supports the board. It must be

accurately measured in order for press to height to be accurate.

“Fixture ID”

–

This feature is intended to verify that the correct fixture (support platen) is used with the

PCB. Entering text into this field does not change anything operationally with the press sequence, but may

be useful for traceability and identifying press sequences for MES systems.

Verification of the fixture ID can be added to the press sequence using the “Verify Fixture ID” condition

from the condition database. Initial setup of this condition must be performed by TE field service

personnel.

“Prompt for Connector Substitution”

–

This check box enables substitution connectors to be selected

at run time. For example, manufacturer “A” may be the prime source for a given connector, but “B” is also

approved as interchangeable on this board. If this box is checked, the operator will be offered a selection

of possible alternates for the connector at run time. Their selection will drive the tool and profile selected

for pressing that connector.

Thus, it is possible to press an alternate connector that requires a different tool and different profile than

the primary connector. The alternates are associated with each other by “substitution codes” that are

defined in the connector database. The associated connectors are individually entered into the database,

but they are

“linked” by a common substitution code. See the connector editor for details on entering

connector substitution codes.

“Connector Name as Label”

–

When this feature is checked, each connector’s Name text (from the

connector database) will be displayed with the connector number on each connector in the runtime PCB

drawing. This option takes priority over the “Use

Connector Message

as Label” option.

“Use

Connector Message

as Label”

–

When this feature is checked, the text entered in the Message

field for each connector position will be displayed with the sequence number on each connector in the

runtime PCB drawing.

Figure 61