6-10

OPERATING PROCEDURES

Models C709 & C717

Operating Procedures

6

7.

Prepare a small amount of a Taylor-approved

cleaning/sanitizing solution with an active chlorine

concentrate of 100 PPM to 200 PPM.

Important!

Use warm water and follow the cleaning/

sanitizing solution manufacturer's specifications.

8.

Sanitize the drip pan(s), feed tube(s), agitator(s), and

hopper cover(s).

9.

Install the agitator(s) back onto the agitator drive

shaft housing(s).

Important!

Make sure the agitator(s) are installed

and the switch is in the Auto or Standby mode, or the

machine will not have a successful Heat cycle.

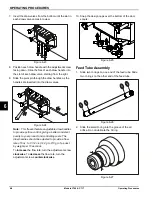

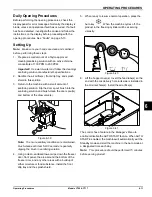

10. Install the end of the feed tube(s) without the mix

delivery hole in its side into the mix inlet hole(s). This

will close the hole in the feed tube(s), preventing the

mix in the hopper(s) from entering the freezing

cylinder(s) during the heating and standby process.

Figure 6-37

11. Install the hopper cover(s) and the drip pans.

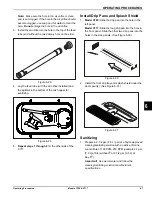

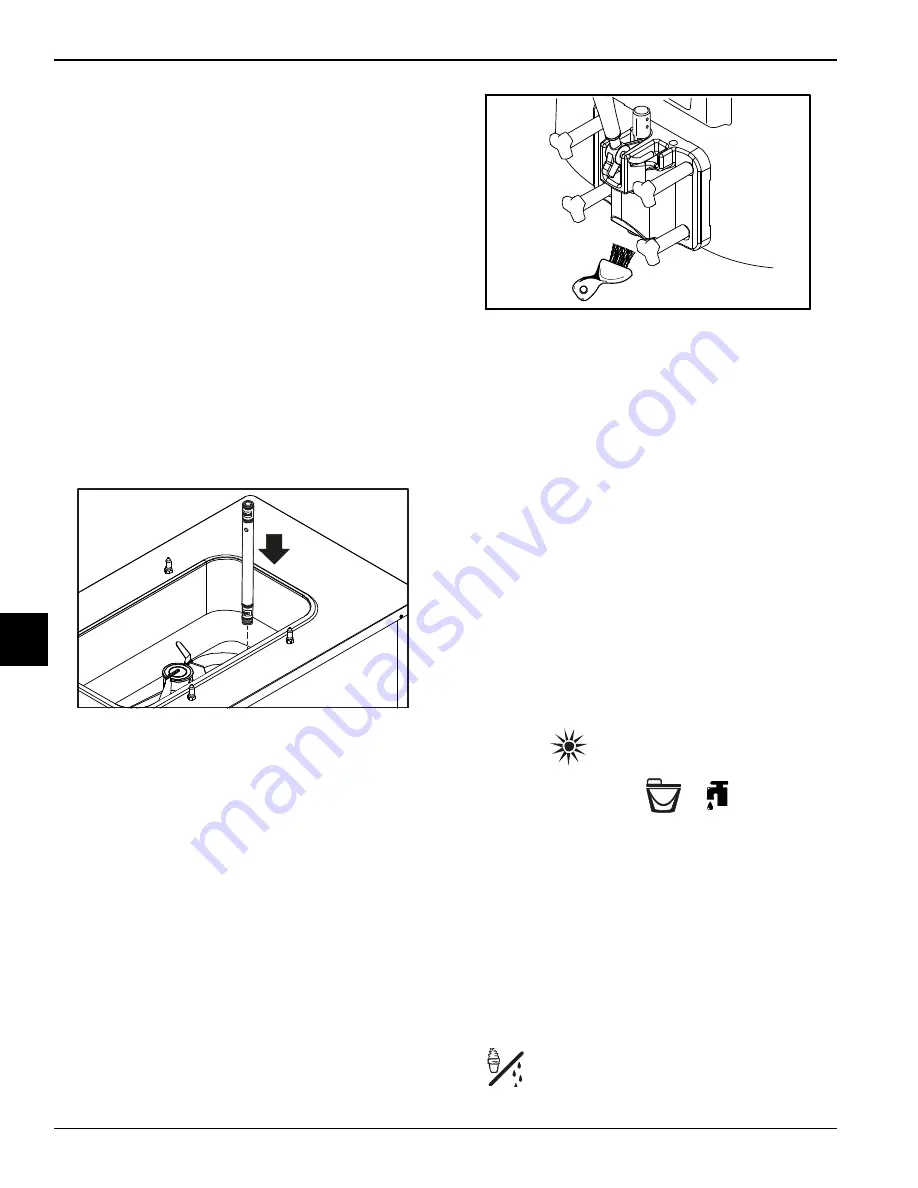

12. Return to the machine with a small amount of

cleaning/sanitizing solution. Dip the door spout brush

into the solution and brush-clean the door spout(s)

and the bottom of the draw valve(s).

Note:

To ensure sanitary conditions are maintained,

brush each item for 60 seconds, repeatedly dipping

the brush in cleaning solution.

Figure 6-38

13. Using a clean, sanitized towel, wipe down the freezer

door, front panel, the area around the bottom of the

freezer door, and any other areas with a buildup of

either moisture or food substance.

The Heat cycle will start when the clock on the

machine reaches the AUTO HEAT TIME set in the

Manager's Menu.

There are 3 phases of the Heat cycle: heating,

holding, and cooling. Each phase has a time limit. If

any one of the three phases fails to reach the proper

temperatures within the time limit, the cycle will

automatically abort and return to the Standby mode.

A failure message will appear on the fluorescent

display to inform the operator that the machine did

not successfully complete the Heat Treatment cycle.

The product may not be safe to serve. The machine

will be locked out (soft lock) of the Auto mode. The

operator will be given the option of selecting the

Heat key

which will begin a new Heat cycle or

selecting the Wash key

/

which will

place the machine into the Off mode to allow a

brush-clean of the machine.

Note:

Once the Heat cycle has started, it cannot be

interrupted. The Heat cycle will take a maximum of

6 hours to complete with full hoppers.

Important! Do not

attempt to draw product or

disassemble the machine during the Heat cycle. The

product is hot and under extreme pressure.

When the Heating cycle is complete, the control will

return to the Standby mode. The Standby key(s)

will illuminate.

12327

10491

Summary of Contents for C709

Page 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Page 22: ...4 10 OPERATOR PARTS IDENTIFICATION Models C709 C717 Operator Parts Identification 4 Notes...

Page 58: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Page 60: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Page 64: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Page 68: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...