- 56 -

Phenomenon Recovery

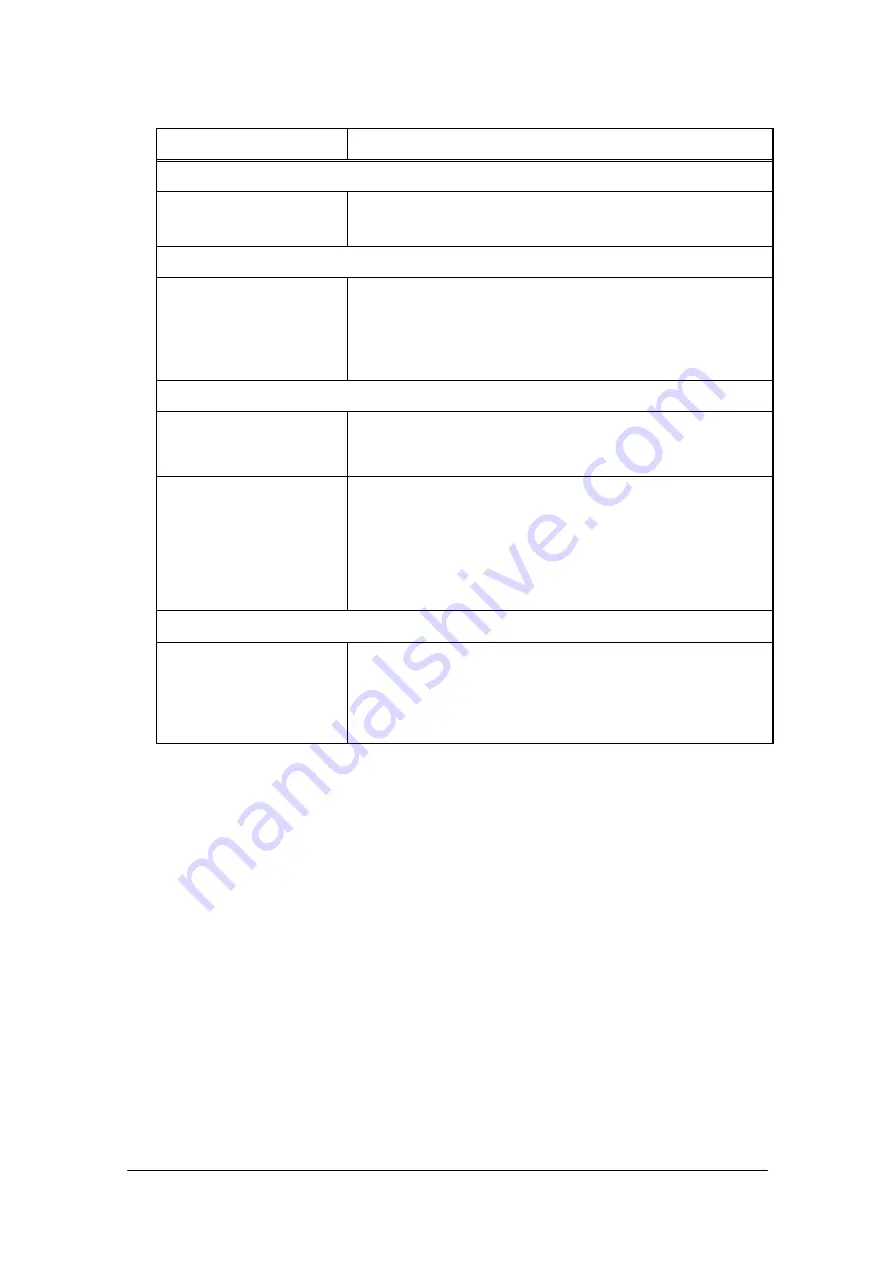

Procedure

Autoloader Performance

Data backup efficiency of the

Autoloader is poor.

Check whether the Autoloader drive is connected to an exclusive SCSI

device and whether it is part of a daisy chain connection with another tape

drive or hard drive.

Operation

Cannot write to data cartridge.

・

Check the access rights of the host device against the file system.

・

Check whether the data cartridge being used is the proper type.

・

Check the write protect tab of the tape and ascertain whether the tape is in

a condition that can accept writing.

・

Replace with a new data cartridge.

Cleaning

The cleaning message is

displayed repeatedly.

・

Replace the current cleaning cartridge with a new one.

・

When a message to the effect that cleaning is required appears on the

LCD even after cleaning of the drive, replace the cleaning cartridge.

Alarm LED is brinking.

“REQ CLNROL” message is

displayed repeatedlly.

・

Execute cleaning of the Roller.See”Section 5.1.2”

Others

The cartridge remains in the

drive.

・

Check the setting of the application software(change setting ,

removing the cartridge after backup job).

・

Eject from operation panel.

・

Execute cleaning of the Roller.See”Section 5.1.2”

・

If the phenomenon has a relapse,contact your nearest Customer Support

Center.