User guide

Inserting the ribbon cassette

11

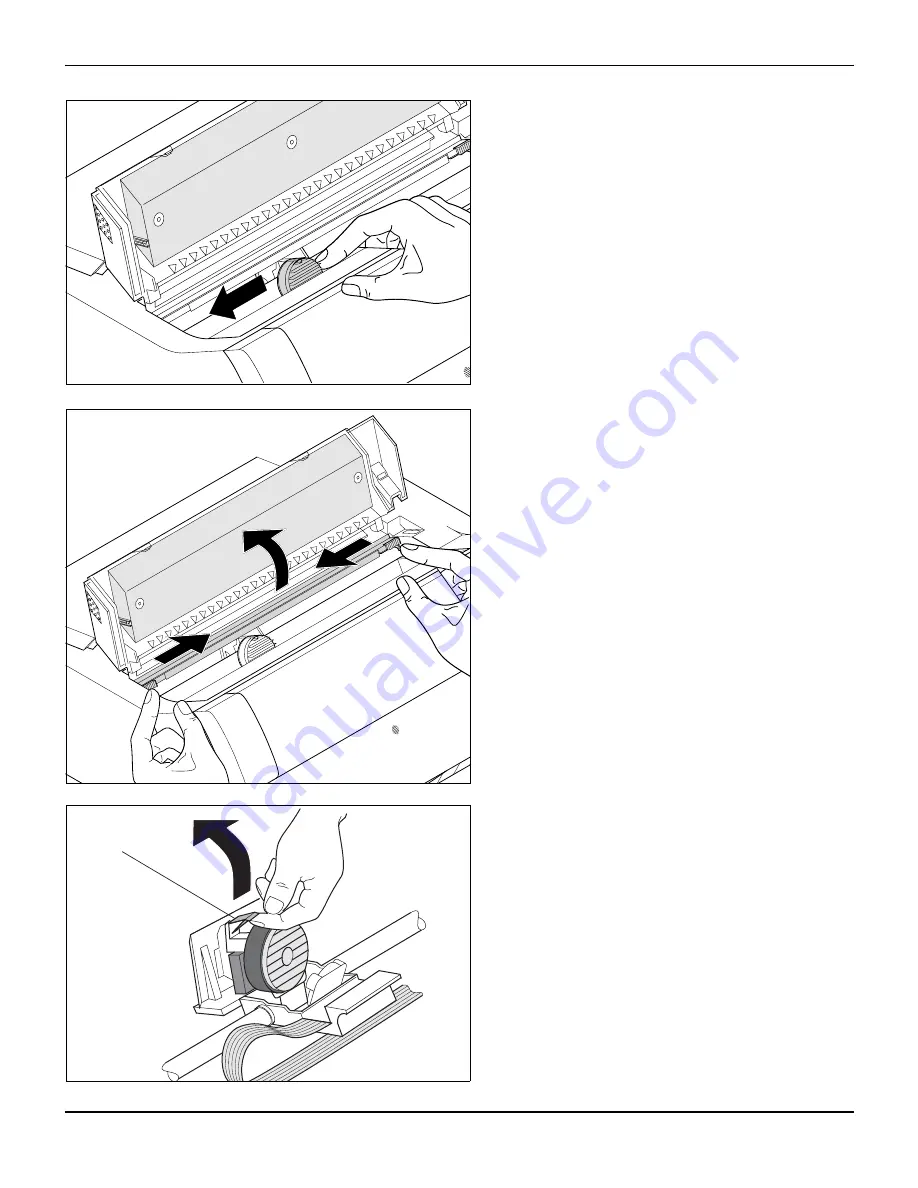

Cautiously slide the print head carriage to the left

stop (viewed from the printer front).

Move the coloured friction tabs to the left and right

(direction of the arrows) as shown in the figure and

raise the friction mechanism.

Raise the coloured insertion tongue A.

A