131

MAINTENANCE

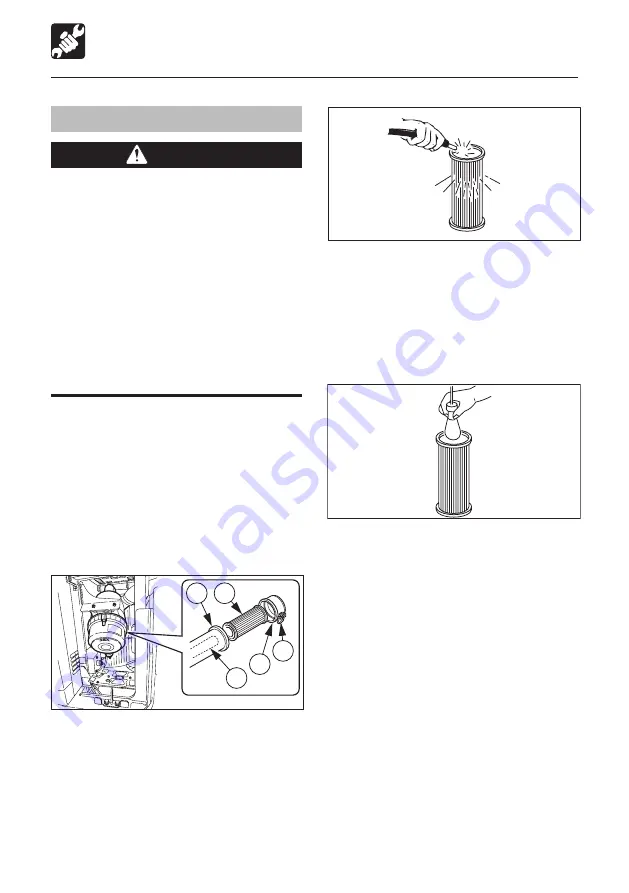

Cleaning the Air Cleaner

WARNING

�

Stop the engine and allow the machine

to cool down before performing

maintenance.

• The engine, muffler, radiator and many

other parts of the machine are hot

directly after the engine is stopped.

Touching these parts will cause

burns.

�

Wear required appropriate equipment

such as safety glasses and filter mask

when using compressed air, as metal

fragments or other objects can fly and

cause serious personal injury.

IMPORTANT: Be careful not to scratch

the element. Do not use an element if it is

damaged.

IMPORTANT: When operating the machine

in very dusty places, inspection and

maintenance should be performed every

day.

1. Open the left side cover.

2. Loosen the clamps (1) and remove the dust

cup (2).

3. Clean the inside of the dust cup (2).

4. Remove the outer element (3).

Do not remove and clean the inner element

(5).

5. Clean the inside of the body (4).

Every 250 Hours

6. Clean the outer element (3) with dried

compressed air {294 to 490 kPa (43 to 71

psi)}.

First blow the air from the inside of the

element along the flutes, then blow the air

from the outside, and finally from the inside

again.

7. Light up the inside of the outer element (3)

with a bulb, inspect it, and replace it if there

are small holes or thin spots.

8. Install the outer element (3).

9. Install the dust cup (2) with the “TOP” mark

at the top, then fasten it with the clamps

(1).

E4G033

E4G034

4 3

2

5

1

W3G050

Summary of Contents for TB175W

Page 6: ...4...

Page 8: ...6...

Page 35: ...33 MEMO...

Page 98: ...96...

Page 103: ...101 TRANSPORT 2 Piece Boom Mono Boom Hoisting the Machine...

Page 168: ...166...

Page 171: ...169 MEMO...

Page 172: ...170 SPECIFICATIONS Machine Dimensions W2K0011 K R G J Q P M V W L N D H B C U S T E F A...

Page 174: ...172 SPECIFICATIONS Operating Range 2 Piece Boom W2K002 J E F G C D K H B A...

Page 176: ...174 SPECIFICATIONS Operating Range Mono Boom W2K003 J K H B A D G F E C...

Page 178: ...176 MEMO...

Page 184: ...182...

Page 212: ...210...

Page 213: ...211 INDEX...