64

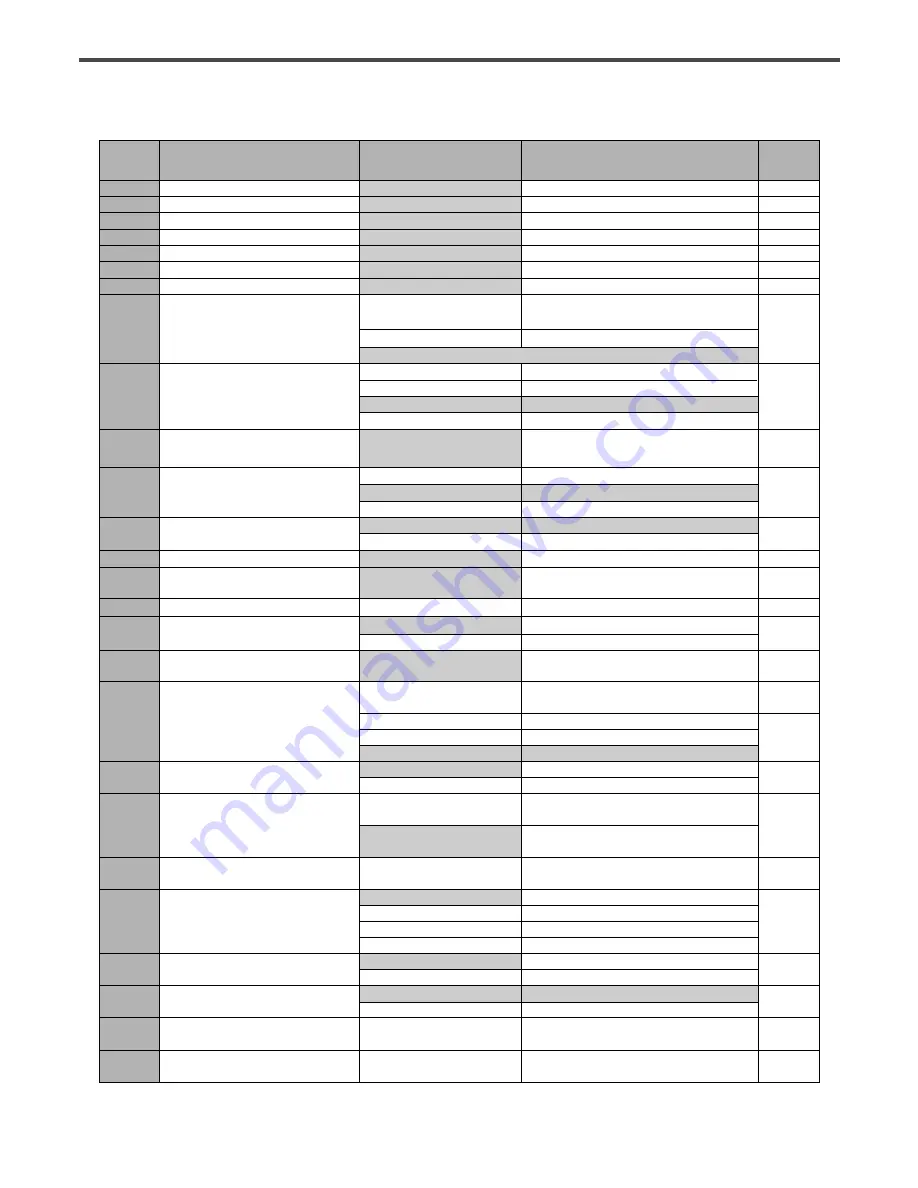

1

0/1

0/1

0/1

0~3

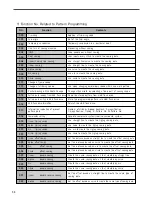

Feed control

In case of temporary stop, control

Pan feed plate

Thread tension adjusting after thread

trimming.

Upper feed plate control

Back/forth jump stitches

Setting-up reference point for

zooming

Palette signal check

071

072

073

074

075

076

077

0

0~31 See “Parameter description related

to general embroidery”.

In case of meeting temporary stop code

while embroidering, control top feed plate

1) CLOSE

Put down the top feed plate

2) OPEN

Hold up the top feed plate

3) FF_NUMBER

1) DISABLE

2) ENABLE

1) DISABLE

2) ENABLE

1

1) MACHINE_ORG

2) SECOND_ORG

3) SEWING_STRT

4) REFER_PNT

1) DISABLE

2) ENABLE

1) DISABLE

2) ENABLE

Control the top feed plate according to Article 060

Do not use thread tension adjusting plate after thread trimming.

Use thread tension adjusting plate after thread trimming.

Sewing will be allowed whether the

upper feed plate is opened or closed.

Sewing will not be allowed when the

upper feed plate is opened.

User can define stitch value to move.

1~100 [Stitch]

Zooming based on the machine origin.

Zooming based on the second origin set by user.

Zooming based on sewing starting point.

Zooming based on the reference point defined by user at any location.

1

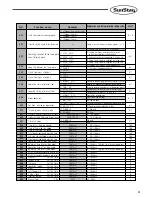

Sewing limit set-up

078

Not used (at the factory)

Used

Do not use signal on the upper feed plate sensor.

Use signal on the upper feed plate sensor.

50[1*50mm]

(For 5050)

X-axis forward direction sewing limit

set-up

079

Sets the size of X-axis forward direction as desired

(1~250)

1

-50[1*50mm]

(For 5050)

X-axis reverse direction sewing limit

set-up

080

Sets the size of X-axis backward direction as

desired (-1~-250)

070

Whether to use the function to detect

fall of pressure

1) DISABLE

2) ENABLE

1) Do not use pressure reduction sensor.

2) Use pressure reduction sensor.

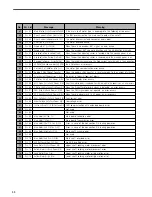

NO.

Function name

Contents

Explanation and factory-installed setting value

Unit

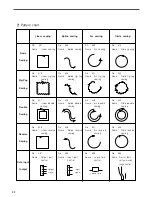

1

10

10

10

10

10

10

0/1

0~2

1

0~2

1

100

Feeding plate

Duty

Trimming

Duty

Loosening thread

Duty

Wiper

Duty

Left feed plate

Duty

2 step stroke

Duty

Inverting device

Duty

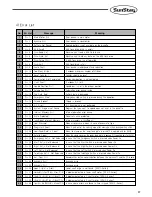

Reading order when number of same

pattern data exist in memory

055

056

063

064

065

067

068

057

058

Extension/Reduction mode

Stitch-NUM:It is not applied

(It is going to apply later)

059

060

061

Number to be performed chain stitch

062

Change of chain number

Reduction stitch before work completion

Reduction speed before work completion

40~48%

30~80%

30~80%

30~80%

43%

50%

50%

50%

30~80%

80%

30~80%

80%

30~80%

80%

★ The reading order when the same pattern

data numbers exist in the internal memory

1) DISABLE

1) Read first from a USB flash drive

2) ENABLE

2) Read first from a internal memory

★ It settles the way of reduction and extension for pattern

1) DISABLE

Extension and reduction are impossible

2) STITCH_LEN

Extension and reduction by a stitch width

3) STITCH_NUM

Extension and reduction by a number of stitch

0

0~16

0:General sewing, Over 1: Chain sewing

1) MANUAL

Automatic change

2) AUTO

Manual change by enter key

3) EXTERNAL

Change by outward input

4[STITCH]

Change to 2~16

4

069

Thread trimming delayed time

72[ms]

52~1020[ms]

400[spm]

SPS/C-Series:200[spm]

200~500spm

066

Clamp Setting for Chain Sewing

1) DISABLE

2) ENABLE

Disabled (default)

Enabled

Summary of Contents for SPS/E-5050 Series

Page 2: ......